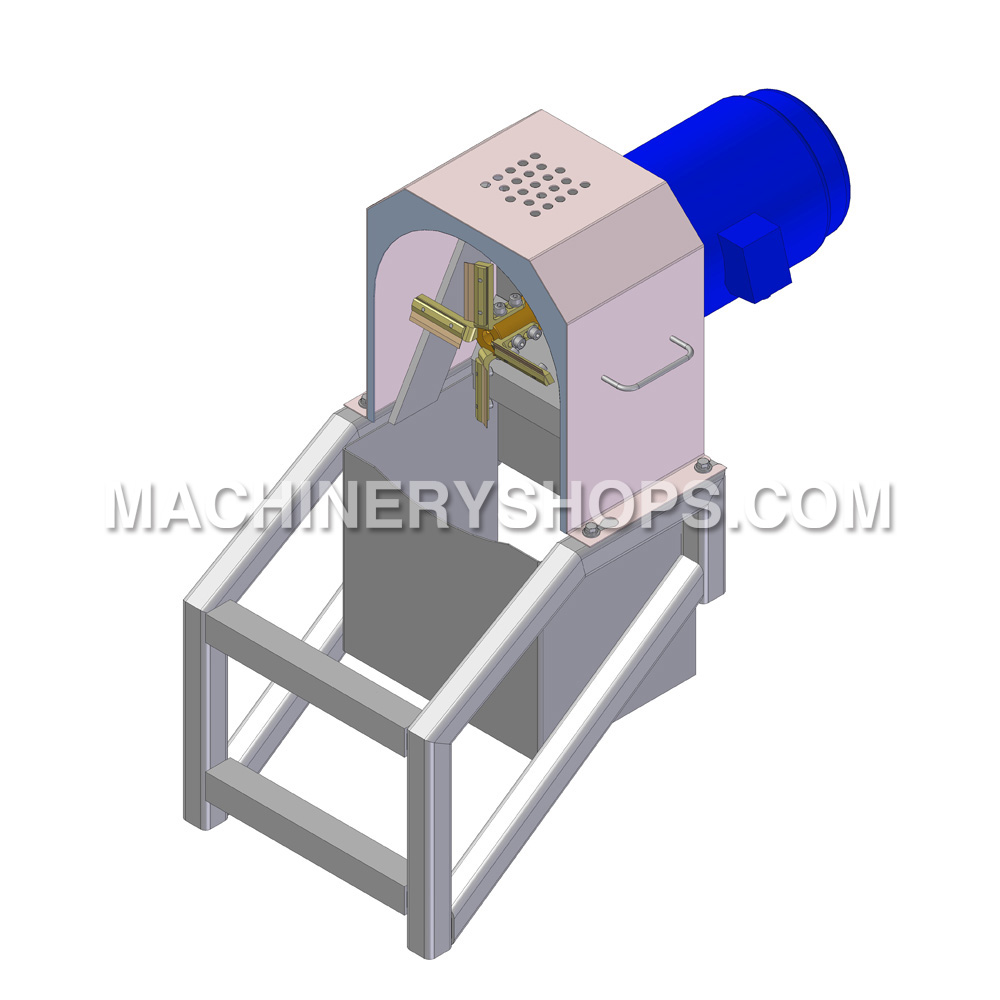

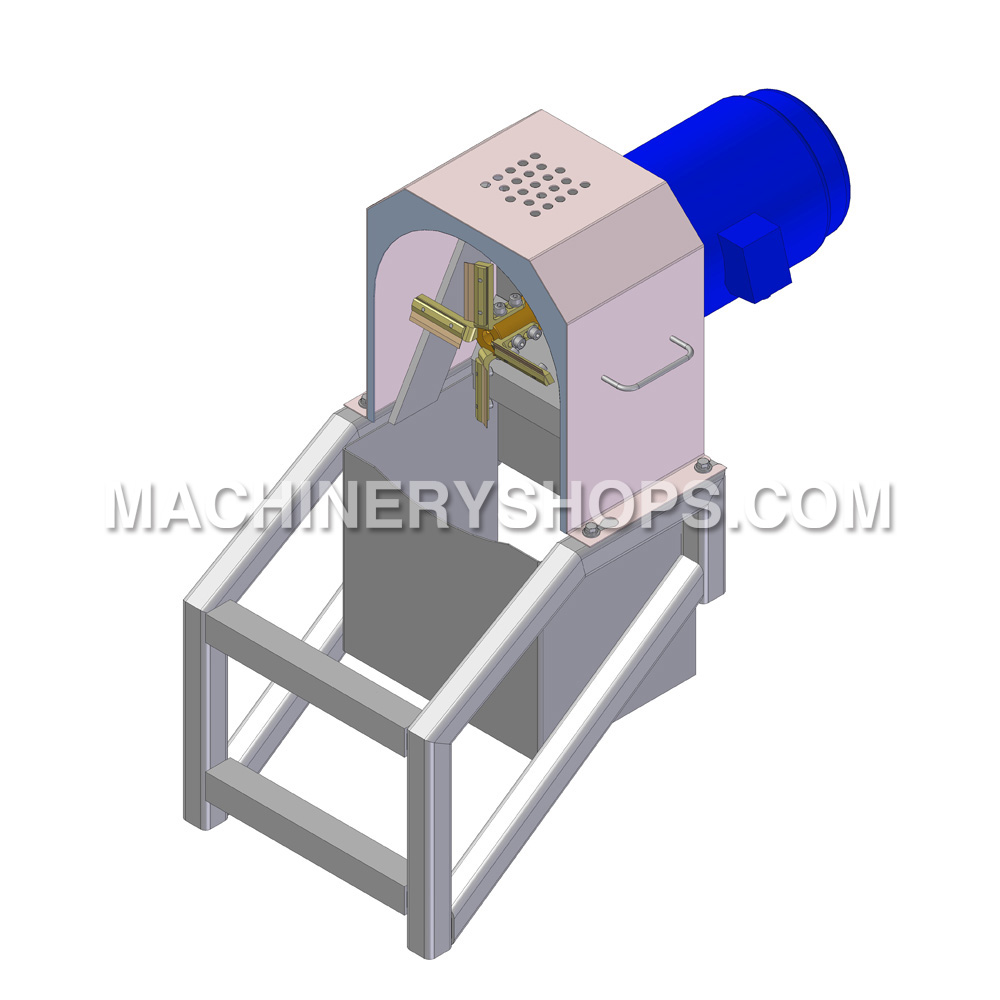

The PHG135 type dry-way extruder is mainly used in producing of expanded soybean and corn etc.

This extruding machine is possessed of cooking, sterilizing, extruding, dewatering and stabilizing treatment functions. Application of extrusion technology is the new direction of feed industry development.

This machine adopts dry-way extrusion technology, simple technology and wide adaptability. By using self-heating method, the material can be cooked to 130~150 ℃ without conditioner and boiler unit. The extruded material can be long-term stored with properly water content. The material can be packed after cooling treatment. Step-less speed regulation makes this type machine stand out for the easy operation, compact conformation and reliable performance.

PHG135 type extruding machinery is composed of hopper, positive displacement screw feeding device, water adding system, extruding chamber, cutting device (select), drive mechanism and machine frame.

Being an important part of feed extruder, extruding chamber is composed of main shaft, extruding screw rod, tapered pressure ring, wear ring and extruding sleeve. The extruding screw rod adopts segmental structure, equal diameter and variable pitch form to meet the demand for flexible assemble of different screw rods according to different raw materials. Configure the tapered pressure rings with different diameters to adjust and control the temperature and pressure in the chamber during extruding process. The extruding sleeve is composed of a feeding extruding chamber part, two middle extruding chamber parts and a discharging extruding chamber.

9/25/2013

9/24/2013

Production Process with Paddle Mixer

The SJHS2A Double-circle Paddle Mixer is widely used for mixing powdery and special granular materials in feed industry. Mixing machine is playing a vital role in feed production. It is fair to say that if proportioning system is disjoined from mixer, even with advanced manufacturing processes, the production will become meaningless. Therefore, the quality and performance of mixing machine directly influences survival and development of feed mills. Stable-performance equipment not only helps enterprises to keep making profits but also reduce large sum of money for maintenance and repairing.

(1) Feeding

Solid materials

The materials can be directly fed from the bin (see Fig.2-7 005) controlled by a lock gate (see Fig.2-7 006) after weighting with the proportion scales (see Fig. 2-7 001), and also can be fed via a covering equipment or via an operator (see Fig.2-3 003) at the manual dumping bit (see Fig.2-7 004).

Liquid (if necessary)

Liquid is generally fed into the mixing machine via the liquid addition system (see Fig. 2-7 010).

(2) Discharging

The mixtures conveyed from mixer (see Fig. 2-7 007) shall be collected by a surge bin (see Fig. 2-7 008);

And the volume of surge bin should be 1.5 times more than that of feed mixer. The surge bin usually has an access door (manhole) and a glass inspection window; the lower part shall have a lock gate or conveying equipment (see Fig. 2-7 009);

The upper end of air-return duct (see Fig. 2-7 009) is connected to the surge bin or that above the scale to ensure stably feeding. In addition, the surge bin shall be removable for maintainability; the environmental protection equipment can be equipped at the outlet to prevent dust pollution of the surge bin.

(1) Feeding

Solid materials

The materials can be directly fed from the bin (see Fig.2-7 005) controlled by a lock gate (see Fig.2-7 006) after weighting with the proportion scales (see Fig. 2-7 001), and also can be fed via a covering equipment or via an operator (see Fig.2-3 003) at the manual dumping bit (see Fig.2-7 004).

Liquid (if necessary)

Liquid is generally fed into the mixing machine via the liquid addition system (see Fig. 2-7 010).

(2) Discharging

The mixtures conveyed from mixer (see Fig. 2-7 007) shall be collected by a surge bin (see Fig. 2-7 008);

And the volume of surge bin should be 1.5 times more than that of feed mixer. The surge bin usually has an access door (manhole) and a glass inspection window; the lower part shall have a lock gate or conveying equipment (see Fig. 2-7 009);

The upper end of air-return duct (see Fig. 2-7 009) is connected to the surge bin or that above the scale to ensure stably feeding. In addition, the surge bin shall be removable for maintainability; the environmental protection equipment can be equipped at the outlet to prevent dust pollution of the surge bin.

9/23/2013

Top-notch Steel Structure Engineering from Muyang

Since its founding in 1996, Muyang Steel Structure Co. Ltd has been committed to spearheading development of steel structure technology with consistent technical innovation and meticulous product management. Its scope of business covers design, structural steel fabrication and installation of civil steel structure buildings, tunnel and bridge steel structure for transportation facilities.

The company now employs over 100 technical staff and owns fixed assets of RMB 50000000 including over 200 units of world-advanced capital equipment. With long-term good business relations with many well-known companies including Hope Group(Sicuan), Tongwei Group(Sicuan), Yangzhou CIMC Tonghua Special Vehicles Co.,Ltd., Liuhe Group(Shandong), Suning Group, Jiangsu Sanxiao Group, CSC Group, Jiangsu Chengde Steel Pipe Co.Ltd, Anhui Jiatong Group, China Railway First Group Co. Ltd., China Railway Eighteenth Group Co.Ltd,. China Petroleum Pipeline and Equioment Corporation, Nanjing Dadi Construction Group, CJ Liaocheng Co., Yangzhou Yongfeng Paper Company and so on, Muyang Steel Structure Co. Ltd. has completed over 1000 steel structure buildings and projects in China and export to USA, Japan, Australia, Russia, Sadui Arabia, and many other countries.

In keeping with its corporate sprit featuring innovation, responsibility, cooperation and efficiency, Muyang Steel Structure Co. Ltd. will continue its perseverant efforts aimed at "laying a solid foundation for a century's glory by creating a world-class brand". Muyang steel structure engineering features:

1. Design and construction at the national first-level with qualification;

2. Involved with steel architecture designing, fabricating and installing;

3. Thousands of steel structure engineering and project contracting experience;

4. Global service network system.

The company now employs over 100 technical staff and owns fixed assets of RMB 50000000 including over 200 units of world-advanced capital equipment. With long-term good business relations with many well-known companies including Hope Group(Sicuan), Tongwei Group(Sicuan), Yangzhou CIMC Tonghua Special Vehicles Co.,Ltd., Liuhe Group(Shandong), Suning Group, Jiangsu Sanxiao Group, CSC Group, Jiangsu Chengde Steel Pipe Co.Ltd, Anhui Jiatong Group, China Railway First Group Co. Ltd., China Railway Eighteenth Group Co.Ltd,. China Petroleum Pipeline and Equioment Corporation, Nanjing Dadi Construction Group, CJ Liaocheng Co., Yangzhou Yongfeng Paper Company and so on, Muyang Steel Structure Co. Ltd. has completed over 1000 steel structure buildings and projects in China and export to USA, Japan, Australia, Russia, Sadui Arabia, and many other countries.

In keeping with its corporate sprit featuring innovation, responsibility, cooperation and efficiency, Muyang Steel Structure Co. Ltd. will continue its perseverant efforts aimed at "laying a solid foundation for a century's glory by creating a world-class brand". Muyang steel structure engineering features:

1. Design and construction at the national first-level with qualification;

2. Involved with steel architecture designing, fabricating and installing;

3. Thousands of steel structure engineering and project contracting experience;

4. Global service network system.

9/22/2013

Main Motor and Rotor Assembly for MUZL 610TW Type Pellet Mill

Main motor

This type of pelleting machine includes two main motors, which are symmetrically installed at both sides of the pellet mill.

The two motors shall rotate in the same direction and finally the ring die shall rotate in clockwise.

The two motors shall startup in star form at the same time, while under normal operation speed the one is transmitted to a triangle connection firstly, and the other also to a triangle operation about five seconds later.

Two motors must run at a same direction and commissioned separately before commissioning and starting of this machine.

Rotor assembly

Main components of rotor assembly are shown in Fig 2.3.

The oil-way of rotor assembly shall be kept unobstructed, after filling the oil from oil nozzle of distributer at rear end, the lubricating oil leading to press roller bearings shall overflow from the seal plate at the end of the press roller after being filled up, and lubricating oil leading to rotor bearings shall overflow from the clearance between the rotor and main shaft disc after being filled up.(It is guaranteed by the oil seal installation direction of the rotor)

Generally, in good lubrication, the service life of the bearings and oil seals of the rotor are longer and they are uneasy to be damaged. It is suggested to ask pellet mill experts of Muyang Group for guide when replacing bearings and oil seals.

Pay attention to abrasion of the cone face of driving flange of the ring die, see Section 7.5 for assembling and disassembling as well as maintenance.

Shear pin assembly

The main parts of the shear pin assembly are shown as Fig.2.5.

When there is large iron block or other impurities entering between the ring die and press roller, in which case, the toque delivered by main shaft will exceed the shear force of the shear pin (part 3), and the shear pin will be sheared off and drove the main shaft rotating with the rotor, the limit switch (part 5) will be cut off to stop the main motor, and take the effect of protecting ring die and press roller.

Restore the Shear pin disc (part 2) to replace a new shear pin after it is sheared off.

This type of pelleting machine includes two main motors, which are symmetrically installed at both sides of the pellet mill.

The two motors shall rotate in the same direction and finally the ring die shall rotate in clockwise.

The two motors shall startup in star form at the same time, while under normal operation speed the one is transmitted to a triangle connection firstly, and the other also to a triangle operation about five seconds later.

Two motors must run at a same direction and commissioned separately before commissioning and starting of this machine.

Rotor assembly

Main components of rotor assembly are shown in Fig 2.3.

The oil-way of rotor assembly shall be kept unobstructed, after filling the oil from oil nozzle of distributer at rear end, the lubricating oil leading to press roller bearings shall overflow from the seal plate at the end of the press roller after being filled up, and lubricating oil leading to rotor bearings shall overflow from the clearance between the rotor and main shaft disc after being filled up.(It is guaranteed by the oil seal installation direction of the rotor)

Generally, in good lubrication, the service life of the bearings and oil seals of the rotor are longer and they are uneasy to be damaged. It is suggested to ask pellet mill experts of Muyang Group for guide when replacing bearings and oil seals.

Pay attention to abrasion of the cone face of driving flange of the ring die, see Section 7.5 for assembling and disassembling as well as maintenance.

Shear pin assembly

The main parts of the shear pin assembly are shown as Fig.2.5.

When there is large iron block or other impurities entering between the ring die and press roller, in which case, the toque delivered by main shaft will exceed the shear force of the shear pin (part 3), and the shear pin will be sheared off and drove the main shaft rotating with the rotor, the limit switch (part 5) will be cut off to stop the main motor, and take the effect of protecting ring die and press roller.

Restore the Shear pin disc (part 2) to replace a new shear pin after it is sheared off.

9/18/2013

MUZL610 Series Pellet Mill

MUZL610-type pellet mill is an advanced pellet mill, which is of Jiangsu Muyang Group manufactured. The entire manufacturing process is in full accordance with international technical standards.

Application and adaptability

(1) This pellet mill is specially used for animal feed processing, generally for processing powdery, foldable and easily pelletized materials.

(2) For ensuring the operation safety of the machine, the altitude of the service region of this machine should be less than 1000m, temperature range 5℃~40℃, and air relative humidity range 30%~ 85%.

(3) Do not used in food processing.

(4) When the region does not accord with the above conditions, in order to be given special instructions.

Main features and functions of the equipment

(1) MUZL610-type pelleting machine is an advanced pellet mill, which is of Jiangsu Muyang Group manufactured. The entire manufacturing process is in full accordance with international technical standards.

(2) Double-motor and V-belt driving system is adopted for this machine type, which is characterized by ideal drive ratio, great driving moment, smooth rotation, high output, low noise, and easy operation and maintenance.

(3) This type of machine can be fitted with many kinds of ring dies with φ1.5~ φ12 die holes and different thickness, so customers can select them for use as required to achieve the optimum technical and economic efficiency.

(4) Advanced frequency control motor is adopted for this machine type to feed material, equipped with overload protection devices, outside discharging mechanisms and Magnetic separating device.

(5) Various conditioners are available, such as single-conditioner, double-conditioner, triple-conditioner, different diameter cylinder conditioner and feed etc.

Application and adaptability

(1) This pellet mill is specially used for animal feed processing, generally for processing powdery, foldable and easily pelletized materials.

(2) For ensuring the operation safety of the machine, the altitude of the service region of this machine should be less than 1000m, temperature range 5℃~40℃, and air relative humidity range 30%~ 85%.

(3) Do not used in food processing.

(4) When the region does not accord with the above conditions, in order to be given special instructions.

Main features and functions of the equipment

(1) MUZL610-type pelleting machine is an advanced pellet mill, which is of Jiangsu Muyang Group manufactured. The entire manufacturing process is in full accordance with international technical standards.

(2) Double-motor and V-belt driving system is adopted for this machine type, which is characterized by ideal drive ratio, great driving moment, smooth rotation, high output, low noise, and easy operation and maintenance.

(3) This type of machine can be fitted with many kinds of ring dies with φ1.5~ φ12 die holes and different thickness, so customers can select them for use as required to achieve the optimum technical and economic efficiency.

(4) Advanced frequency control motor is adopted for this machine type to feed material, equipped with overload protection devices, outside discharging mechanisms and Magnetic separating device.

(5) Various conditioners are available, such as single-conditioner, double-conditioner, triple-conditioner, different diameter cylinder conditioner and feed etc.

9/17/2013

Installation of Bridge-breaking Feeding Bin and Feeder

One of basic reference data for the control system of the extruder is the material flow rate, and the addition level of water, steam and other liquids in the system shall refer to the material flow rate, therefore the stability of material flow will directly affect that of the whole extruder producing. To ensure stable materials flow, weighing feeding is used in this system, namely, put the whole feeding bin and feeder onto the weighing sensor, so as to form a closed-loop control among weighing sensor, frequency-converted feeder and computer, and then realize feeding.

A basic requirement to the weighing feeding of the feed extruder is a flexible connection between upper and lower interface, namely, the flexible connection between bridge-breaking feeding bin and pneumatic gate at upper part of the bin, as well as the flexible connection between feeder outlet and conditioner inlet, canvas is usually used as the material for flexible connection for this two parts.

Installation of weighing sensor is another important factor affecting the feeding. There are generally two methods for sensor installation: hanging installation and supporting installation, which will be used as required in the site. Necessary measures shall be taken to ensure stability of bin body while hanging installation is used. During production of extruding machine, falling down of materials, when feeding to the feeding bin, will make the whole bin body waggled, the waggling extent and time will closely related to the length of sensor's tie bar. Although the control procedure uses the data prior to feeding for the data in the period of material entering the bin, waggling of the body will be also caused after material enters the bin, the weighing accuracy of sensor will be directly affected, and thus the control procedure will also be influenced, therefore it is required to equip with a limit device at the lower part of bin, and this device shall not affect weighting.

The another method is supporting installation, which will not cause waggling, but the whole bin body on the extruding machinery tends to translocation, therefore sensor should be fixed on a bracket during installation, and it is required to mount limit blocks at both sides of each ear of the feeding bin, so as to prevent the whole bin body from translocation.

It is necessary to pay attention to the position of access door during installation of bridge-breaking feeding bin, and the maintenance platform should be mounted at the lower part of access door while ensuring that the access door can be opened.

A basic requirement to the weighing feeding of the feed extruder is a flexible connection between upper and lower interface, namely, the flexible connection between bridge-breaking feeding bin and pneumatic gate at upper part of the bin, as well as the flexible connection between feeder outlet and conditioner inlet, canvas is usually used as the material for flexible connection for this two parts.

Installation of weighing sensor is another important factor affecting the feeding. There are generally two methods for sensor installation: hanging installation and supporting installation, which will be used as required in the site. Necessary measures shall be taken to ensure stability of bin body while hanging installation is used. During production of extruding machine, falling down of materials, when feeding to the feeding bin, will make the whole bin body waggled, the waggling extent and time will closely related to the length of sensor's tie bar. Although the control procedure uses the data prior to feeding for the data in the period of material entering the bin, waggling of the body will be also caused after material enters the bin, the weighing accuracy of sensor will be directly affected, and thus the control procedure will also be influenced, therefore it is required to equip with a limit device at the lower part of bin, and this device shall not affect weighting.

The another method is supporting installation, which will not cause waggling, but the whole bin body on the extruding machinery tends to translocation, therefore sensor should be fixed on a bracket during installation, and it is required to mount limit blocks at both sides of each ear of the feeding bin, so as to prevent the whole bin body from translocation.

It is necessary to pay attention to the position of access door during installation of bridge-breaking feeding bin, and the maintenance platform should be mounted at the lower part of access door while ensuring that the access door can be opened.

9/16/2013

Important Explanation on SWFP Series Fine-grinding Hammer Mill

Congratulations on your purchase of Muyang Brand Hammer mill. This design of Chaoyue Fine-Grinding Hammer Mill can both fulfill your requirements to grind different raw materials and also improve the material grinding efficiency. Prior to use, please read through this Operation Manual and well know the safety points, different performances, requirements to installation and operation etc. For this Hammer mill, so that you can expertly operate and use this machine, and create more benefits for you.

This Operation Manual shall be provided to your working personnel in charge of operating and managing the equipment manufactured by Jiangsu Muyang Group which is a successful grinding machine manufacturer. Therefore, it is very important to deliver these documents to them.

A check on appearance should be made immediately when the equipment is transported to the destination. If it is sure there is any damage caused during transport, a necessary claim procedure must be taken according to the supply contract. The repair expense shall be borne by relevant risk undertaker.

The grinding machine, which cannot be installed in predetermined place immediately, must be stored in a weatherproof place with facilities against external infringement in original packages. Any loss arising from storage shall be only conducted as per the principle specified in the Supply Contract.

The equipment and parts manufactured by Jiangsu Muyang Group shall be installed only by the trained technical personnel based on installation specifications provided together with the equipment.

If several structures on the grinding machinery are introduced in the documents provided, only the structures specified in Supply Contract shall be effective. We reserve the right of improvement before delivery.

Startup and commissioning shall only be done by trained personnel. The operators shall know the instructions and operation regulations in provided documents before startup. Lubricating oil shall be filled before startup, such as oil for variable speed devices.

The accident prevention rules in related documents must be well known and strictly obeyed. Jiangsu Muyang Group devotes to manufacturing machinery equipment according to the latest National Safety Standards (CE Certification Standards). Customers shall tell us the local safety rules before manufacturing. Additional expenses there from shall be borne by customers.

The leaders of an enterprise owning the equipment from Jiangsu Muyang Group shall have the duty to allow the operators to know the operating instructions, and shall point out where the especial dangers are during operating these grinding machines.

This Operation Manual shall be provided to your working personnel in charge of operating and managing the equipment manufactured by Jiangsu Muyang Group which is a successful grinding machine manufacturer. Therefore, it is very important to deliver these documents to them.

A check on appearance should be made immediately when the equipment is transported to the destination. If it is sure there is any damage caused during transport, a necessary claim procedure must be taken according to the supply contract. The repair expense shall be borne by relevant risk undertaker.

The grinding machine, which cannot be installed in predetermined place immediately, must be stored in a weatherproof place with facilities against external infringement in original packages. Any loss arising from storage shall be only conducted as per the principle specified in the Supply Contract.

The equipment and parts manufactured by Jiangsu Muyang Group shall be installed only by the trained technical personnel based on installation specifications provided together with the equipment.

If several structures on the grinding machinery are introduced in the documents provided, only the structures specified in Supply Contract shall be effective. We reserve the right of improvement before delivery.

Startup and commissioning shall only be done by trained personnel. The operators shall know the instructions and operation regulations in provided documents before startup. Lubricating oil shall be filled before startup, such as oil for variable speed devices.

The accident prevention rules in related documents must be well known and strictly obeyed. Jiangsu Muyang Group devotes to manufacturing machinery equipment according to the latest National Safety Standards (CE Certification Standards). Customers shall tell us the local safety rules before manufacturing. Additional expenses there from shall be borne by customers.

The leaders of an enterprise owning the equipment from Jiangsu Muyang Group shall have the duty to allow the operators to know the operating instructions, and shall point out where the especial dangers are during operating these grinding machines.

Subscribe to:

Posts (Atom)