If you have an improved, cheaper and safer end product you will have the edge over competitor and eventually your profit ratio. For feed manufacturing industry, technology that help feed manufactures keep leading in the industry has become the primary consideration for making the investment decision, be it greenfield or upgraded project.

For livestock feed production, pretreatment technology is very important, and the basic type of processing used within feed mills usually is pellet conditioner. As concerns over feed cost increased, new pretreatment technologies are asked to widen the scope of available raw materials. And higher standards on feed nutrition and feed safety in breeding farms also require improved technologies and equipment for production, especially for young animal feed. For these reasons, expander used in pretreatment has become more and more popular in processing lines. However, gelatinization level of end product of traditional expander is limited to 60%. When requirement to starch gelatinization comes up to 70~75%, extruder is a better choice than expander, but it also faces problems of reduced output and increased energy consumption.

As a technology problem solver, Muyang introduces a new technology specialized for piglet feed production. The so call "fully extrusion and low-temperature pelleting system" may initially be more expansive than the expander and pelleting system, but when makes a simple comparison of the increased profit from high quality end product and the reduced tonnage power consumption, it can normally be shown to be cost effective, and this is without taking into account the probable increased efficiency of the extruder machinery itself.

Feed intake efficiency comparison

Results of tests demonstrated that piglets fed with feed produced by fully extrusion and low-temperature pelleting line showed significant improvement on feed intake, weight gain and intestinal health. It is because:

1) Fully extrusion process can achieve products tasty flavor and better palatability;

2) Fully extrusion and low temperature pelleting can diminish nutritional ingredients loss during processing, and ensure enough nutrition and energy for weanling pigs, resulting in increased weight gain;

3) Fully extrusion can contribute to higher starch gelatinization and eliminates the effects of anti-nutritional factors and toxins, which is good for intestinal health.

12/16/2014

12/09/2014

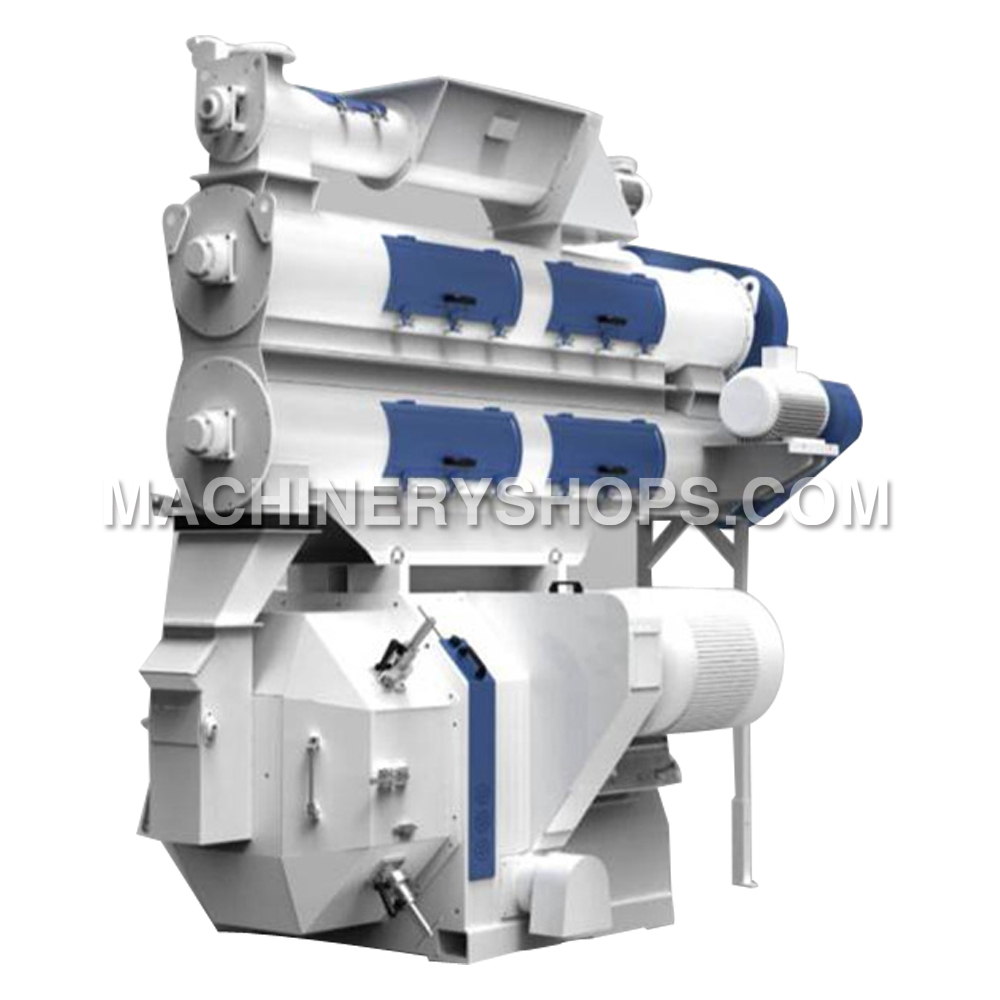

Animal Pellet Feed Production Line

Animal pellet feed production line is the core equipment for feed manufacturers, which can complete the magnetic separation, crushing, mixing, granulating, lifting, cooling, screening, product packaging and dust removal by ventilation, electrical control and other functions, this paper will introduce what equipment does animal pellet feed production line have?

According to the process flow, complete feed production line can be divided into four sections, and each section has specific equipment:

1.Preclean and grinding section: in this system, feed raw materials will be received, and hammer mill machine will be used to grinder materials.

2.Mixed section: feed materials which is stored in the mixing chamber will be mixed by twin shaft paddle mixer or screw mixer.

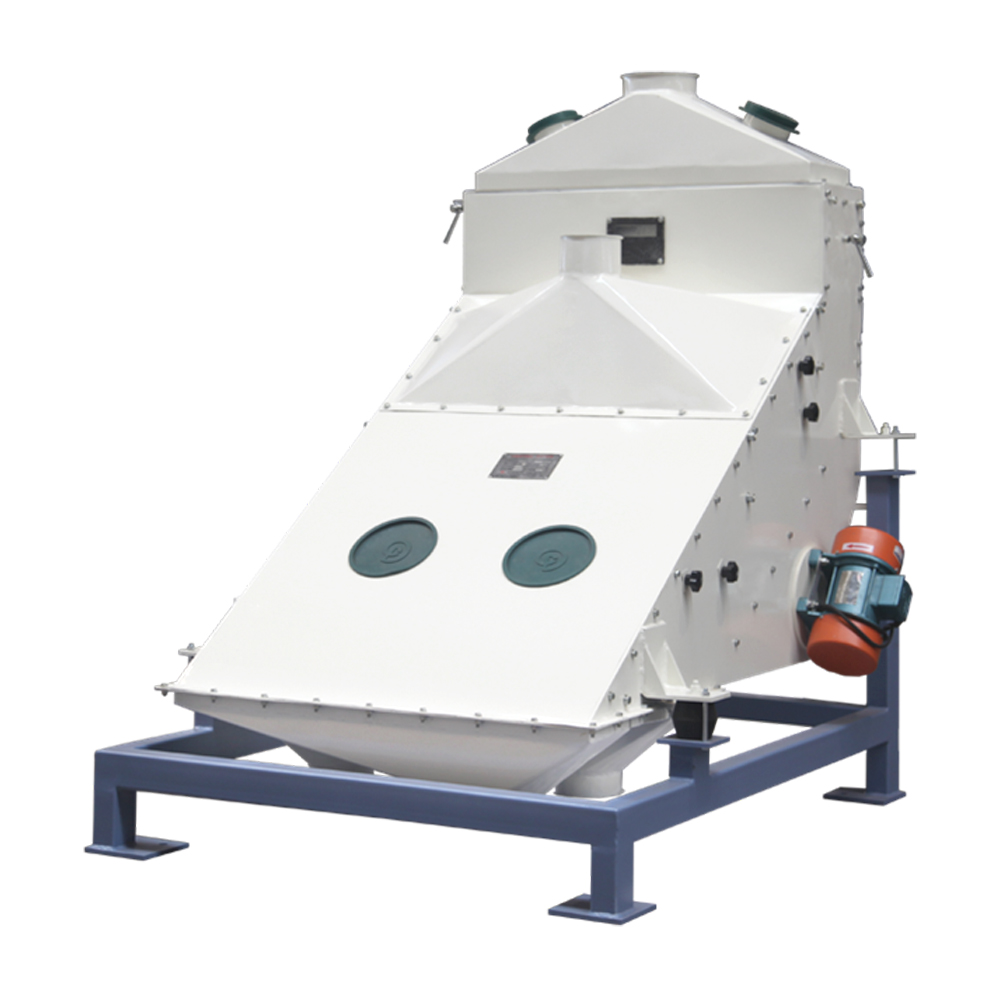

3.Pellet-making, cooling section: in this section, ring die pellet mill or flat die pellet machine is the main animal pellets feed making machine and hot pellets feed made by feed making machine will be cooled by counter flow cooler.

4.Sieving and packing section: Pellet feed after sieving can be packed, in the section, you can choose automatic bagging scale or manual packing.

According to the process flow, complete feed production line can be divided into four sections, and each section has specific equipment:

1.Preclean and grinding section: in this system, feed raw materials will be received, and hammer mill machine will be used to grinder materials.

2.Mixed section: feed materials which is stored in the mixing chamber will be mixed by twin shaft paddle mixer or screw mixer.

3.Pellet-making, cooling section: in this section, ring die pellet mill or flat die pellet machine is the main animal pellets feed making machine and hot pellets feed made by feed making machine will be cooled by counter flow cooler.

4.Sieving and packing section: Pellet feed after sieving can be packed, in the section, you can choose automatic bagging scale or manual packing.

11/30/2014

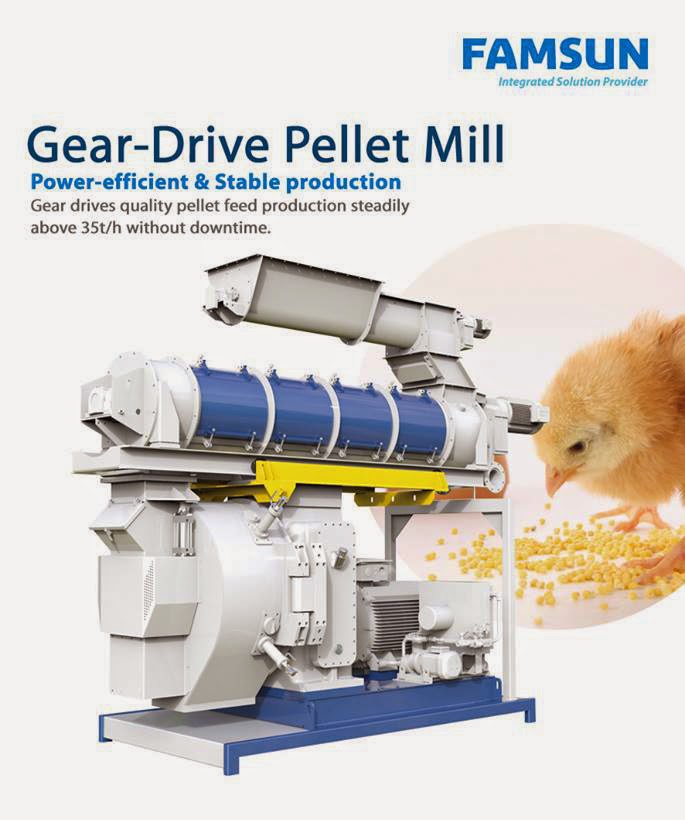

New Product---FAMSUN Gear-Drive Pellet Mill

FAMSUN Gear-Drive Pelleting Machine

Gear-drive for reliable production

High machining and installation precision of gear box contributes to reliable, precise and efficient transmission, bringing in stable production without failure downtime.

Optimal structure for high output and energy-efficiency

Optimized feed-to-pellet defector structure, widened ring die working area (+15~25%) to enable consistent pellet quality, high output and lower energy consumption (possible to reduce power consumption to 6.1kW•h/t for livestock feed production).

Smart control and easy operation

Fuzzy logics is introduced to the controller of the pelleting system to optimize processing parameters, eliminate human factors and achieve more effective production.

Unique die changing and roller adjustment tools for easing labor.

User-friendly operation

CE Standard design details such as overload protection, door protection, gear box protection with liquid level monitoring and iron removing, guard hoods, etc. to ensure safe, reliable and stable production.

Gear-drive for reliable production

High machining and installation precision of gear box contributes to reliable, precise and efficient transmission, bringing in stable production without failure downtime.

Optimal structure for high output and energy-efficiency

Optimized feed-to-pellet defector structure, widened ring die working area (+15~25%) to enable consistent pellet quality, high output and lower energy consumption (possible to reduce power consumption to 6.1kW•h/t for livestock feed production).

Smart control and easy operation

Fuzzy logics is introduced to the controller of the pelleting system to optimize processing parameters, eliminate human factors and achieve more effective production.

Unique die changing and roller adjustment tools for easing labor.

User-friendly operation

CE Standard design details such as overload protection, door protection, gear box protection with liquid level monitoring and iron removing, guard hoods, etc. to ensure safe, reliable and stable production.

11/27/2014

SWFP66*100XM Hammer Mill

Having adapted to the changing needs of customers, Muyang is developing raw material processing solutions designed to further increase output and promote the efficient use of available raw materials.

Facing raw material shortage and high price pressure, feed manufacturers would turn to the alternative ingredients rather than keep the formulation unchanged.

Today, substituting corn with the more available and much cheaper wheat is more acceptable in the feed industry. However, tough and small, wheat grain is hard to be ground, thus raising different requirements to the grinding machine and technology.

Specialized for wheat grinding and with the point of departure to get more value out of wheat without changing the original grinding process, Muyang SWFP66*100XM grinding machinery is developed. The hammer mill is designed to be more compatible to the original process, and most of its spare parts are interchangeable with those of the other Muyang hammer mills. On the other hand, like the other Muyang SWFP hammer mills, this wheat grinding machine i s also characterized by its high energy efficiency, stable performance and less maintenance.

Facing raw material shortage and high price pressure, feed manufacturers would turn to the alternative ingredients rather than keep the formulation unchanged.

Today, substituting corn with the more available and much cheaper wheat is more acceptable in the feed industry. However, tough and small, wheat grain is hard to be ground, thus raising different requirements to the grinding machine and technology.

Specialized for wheat grinding and with the point of departure to get more value out of wheat without changing the original grinding process, Muyang SWFP66*100XM grinding machinery is developed. The hammer mill is designed to be more compatible to the original process, and most of its spare parts are interchangeable with those of the other Muyang hammer mills. On the other hand, like the other Muyang SWFP hammer mills, this wheat grinding machine i s also characterized by its high energy efficiency, stable performance and less maintenance.

11/03/2014

Muyang Attended the 29th Shandong Livestock Exposition

During from October 25th to 26th, the 29th Shandong Livestock Exposition was held in Jinan International Convention and Exhibition Center, the exposition is the largest and highest grade ever, most content-rich, supporting activities carried out most of the time Husbandry event. Muyang carried steel sheds debut in this exhibition.

This year's show, from more than 10 countries and regions with over 20 provinces and autonomous regions, together with 550 companies gathered together to meet this annual event.

Chinese aquaculture industry, large-scale, specialized, intensive maturing

As the largest high-quality aquaculture engineering system solutions for service providers, Muyang was eye-catching. On 25th, Shandong Province, deputy director of Animal Husbandry and Veterinary Bureau Jianjun Tang booth tour guide to visit Muyang, after visiting Muyang devices, he said the success of this event will be held, all-round beckons farming industry scale, specialized, intensive in accelerating the pace, this exhibition of unprecedented scale, totaling more than 1,000 exhibitors, the number of visitors is expected to reach 80,000, the Muyang feed the engineering industry is now an expert in the future, they will certainly accomplish a great deal in Muyang farming industry, leading the development of the industry. Qingdao Muyang responded clutching industry development opportunities, integration of resources, strengthen research and development, adhere to the path of innovation and development, market development effort aquaculture projects, and strive industry first, to do for each device, each ction to each project both lean design, to create a system value, farming machinery to build a world-class leading technology companies.

The rapid development of power industry equipment system

The exhibition, Muyang's breeding sheds steel attracted many farmers to visit the consultation, at specialization, scale, intensive trend, farmers who urgently systematic solution, which is Muyang’s advantage. Muyang's water feed line systems, ventilation and cooling systems to provide customers the perfect solution to the problem encountered in large-scale production. Customers take the initiative to come to counseling, problem overall advantage equipment, function of each device, are focused on customer care, for which the shepherd staff for clients answered. Spiritual Muyang continued to create customer benefits, providing fine service impressed with every customer.

Professional, systems, services is the driving force for sustainable development

Aquaculture engineering system for customers to create solutions are constantly striving for Qingdao Muyang and its long-term effort and struggle but also won numerous customer recognitions. Animal Husbandry Engineering Co., Ltd. Qingdao shepherd product development, engineering design, manufacture, installation and service as a whole, the main products include steel equipment, poultry rearing automated feeding systems, drinking water systems, animal building room cooling systems, ventilation systems environment and environmental control systems. The company has first-class R & D team, high quality products, quality service for our customers to create the perfect delivery.

In the future, Qingdao Muyang Animal Husbandry Engineering Co., Ltd. will continue to deepen professional capacity, systems, services for industry specialization, scale, intensive to help lead the development of the industry.

Muyang provides its customers with animal feed machines and other large projects like steel structure, raising system, grain slio and other engineering.

This year's show, from more than 10 countries and regions with over 20 provinces and autonomous regions, together with 550 companies gathered together to meet this annual event.

Chinese aquaculture industry, large-scale, specialized, intensive maturing

As the largest high-quality aquaculture engineering system solutions for service providers, Muyang was eye-catching. On 25th, Shandong Province, deputy director of Animal Husbandry and Veterinary Bureau Jianjun Tang booth tour guide to visit Muyang, after visiting Muyang devices, he said the success of this event will be held, all-round beckons farming industry scale, specialized, intensive in accelerating the pace, this exhibition of unprecedented scale, totaling more than 1,000 exhibitors, the number of visitors is expected to reach 80,000, the Muyang feed the engineering industry is now an expert in the future, they will certainly accomplish a great deal in Muyang farming industry, leading the development of the industry. Qingdao Muyang responded clutching industry development opportunities, integration of resources, strengthen research and development, adhere to the path of innovation and development, market development effort aquaculture projects, and strive industry first, to do for each device, each ction to each project both lean design, to create a system value, farming machinery to build a world-class leading technology companies.

The rapid development of power industry equipment system

The exhibition, Muyang's breeding sheds steel attracted many farmers to visit the consultation, at specialization, scale, intensive trend, farmers who urgently systematic solution, which is Muyang’s advantage. Muyang's water feed line systems, ventilation and cooling systems to provide customers the perfect solution to the problem encountered in large-scale production. Customers take the initiative to come to counseling, problem overall advantage equipment, function of each device, are focused on customer care, for which the shepherd staff for clients answered. Spiritual Muyang continued to create customer benefits, providing fine service impressed with every customer.

Professional, systems, services is the driving force for sustainable development

Aquaculture engineering system for customers to create solutions are constantly striving for Qingdao Muyang and its long-term effort and struggle but also won numerous customer recognitions. Animal Husbandry Engineering Co., Ltd. Qingdao shepherd product development, engineering design, manufacture, installation and service as a whole, the main products include steel equipment, poultry rearing automated feeding systems, drinking water systems, animal building room cooling systems, ventilation systems environment and environmental control systems. The company has first-class R & D team, high quality products, quality service for our customers to create the perfect delivery.

In the future, Qingdao Muyang Animal Husbandry Engineering Co., Ltd. will continue to deepen professional capacity, systems, services for industry specialization, scale, intensive to help lead the development of the industry.

Muyang provides its customers with animal feed machines and other large projects like steel structure, raising system, grain slio and other engineering.

10/29/2014

Muyang to showcase FAMSUN feed-to-meat solutions at VIV China 2014

Muyang will showcase a new pellet mill at a 445.5m2 booth during VIV China 2014, held on September 23-25.

The 35T/H pellet mill is the first gear drive press in the FAMSUN pellet mill family. It is developed by the European Institute of Muyang Company.

Driven by a 250kW motor, the feed machine can produce high quality pellets steadily above 35 tonnes/hour without downtime. Besides the exhibited press, a model of 25T/H capacity is also available for this gear drive series to meet different production demands.

The FAMSUN MY 120 Twin-Screw Extruder and the FAMSUN-WEM Automation System will also be showcased and is marketed to aqua feed producers.

In addition, FAMSUN's delicate cage raising systems, flat raising steel structure houses, pig penning systems and farm climate control systems will be seen at VIV China.

The 35T/H pellet mill is the first gear drive press in the FAMSUN pellet mill family. It is developed by the European Institute of Muyang Company.

Driven by a 250kW motor, the feed machine can produce high quality pellets steadily above 35 tonnes/hour without downtime. Besides the exhibited press, a model of 25T/H capacity is also available for this gear drive series to meet different production demands.

The FAMSUN MY 120 Twin-Screw Extruder and the FAMSUN-WEM Automation System will also be showcased and is marketed to aqua feed producers.

In addition, FAMSUN's delicate cage raising systems, flat raising steel structure houses, pig penning systems and farm climate control systems will be seen at VIV China.

10/21/2014

Muyang Single Screw Extruder

The extrusion provides for production of many products with great superiority in comparison with other technologies. Because it almost integrates functions of different equipments in a single process when extruding, the procedures of mixing, extruding, cutting, cooking, forming and drying process in a certain degree can be carried out at the same time. The feed machinery has the following functions and features:

(1) Multi-functionality of the equipment Multi-functionality of the equipment presents as suitable for processing of different materials and able to achieve different ripening degrees (or extrusion degrees) as required when processing the same material. The reasons for one extruder able to achieve multifunction include the following three aspects:

① The screw configuration applies combined-type structure, which can provide different shearing forces for materials through changing some simple rod configurations;

② There are sorts of discharging devices and the discharging area of materials can be adjusted as required.

③ In production, the processing parameters of the feed machine can be adjusted as required.

(2) Uniqueness of the product Other technologies are difficult or cannot produce products and products in certain shapes produced by this extruding operation.

(3) High-quality of the product This extruding operation is extremely effective for high-temperature and short-period processing, it is provided with a better nutrition improvement while effectively reducing different anti-nutritional factors in products and sterilizing.

(4) Effective utilization of energy Ripening degree of products through this extrusion operation is improved greatly. Compared with the other processing technologies or modes, extrusion can ripen material in a great degree, sufficiently use steam and reduce power consumption, and thus process cost can be saved.

(5) Minimum industrial wastewater This extruding can effectively avoid industrial wastewater; this is an outstanding advantage for feed manufacturers bearing the increasing pressure for reducing influences of production activities on surrounding environment.

(1) Multi-functionality of the equipment Multi-functionality of the equipment presents as suitable for processing of different materials and able to achieve different ripening degrees (or extrusion degrees) as required when processing the same material. The reasons for one extruder able to achieve multifunction include the following three aspects:

① The screw configuration applies combined-type structure, which can provide different shearing forces for materials through changing some simple rod configurations;

② There are sorts of discharging devices and the discharging area of materials can be adjusted as required.

③ In production, the processing parameters of the feed machine can be adjusted as required.

(2) Uniqueness of the product Other technologies are difficult or cannot produce products and products in certain shapes produced by this extruding operation.

(3) High-quality of the product This extruding operation is extremely effective for high-temperature and short-period processing, it is provided with a better nutrition improvement while effectively reducing different anti-nutritional factors in products and sterilizing.

(4) Effective utilization of energy Ripening degree of products through this extrusion operation is improved greatly. Compared with the other processing technologies or modes, extrusion can ripen material in a great degree, sufficiently use steam and reduce power consumption, and thus process cost can be saved.

(5) Minimum industrial wastewater This extruding can effectively avoid industrial wastewater; this is an outstanding advantage for feed manufacturers bearing the increasing pressure for reducing influences of production activities on surrounding environment.

9/23/2014

Explosion Protection: Countermeasures against Dust

There are many tips you should you know after you operate Muyang feed machines, and you should know the right means and safety points, then you can avoid unnecessary matters.

1. Common cleaning work

*** Keeping the working site with combustible dust clean is an important condition for safe production.

*** Try not to pile bagged or bulk materials between machines.

*** In order to reduce dust emission to surrounding areas, all conveying devices, cyclone separators and dust collectors should be kept in good condition. Especially, the unsealing phenomena of pipes or top covers should be avoided.

*** In order to reduce dust explosion hazard, dust everywhere must be cleaned out frequently and effectively.

*** Keep all motors free of deposited dust.

2. Frequent inspection and maintenance

*** Regularly Check all V-belts and flat belts for driving conditions, at least once a week, so as to avoid heat generation due to skid.

*** Regularly check the safety feed machine such as speed monitor or the like, at least once a week.

*** Check and clean all the magnetic separators, stoners and sifters regularly, at least once a day.

*** In order to avoid heat generation, it is necessary to regularly check the functions of all main shafts and bearings, at least once a week, and to regularly fill up lubricating oil.

3. Electric apparatus

Regularly check the electric apparatus and articles, and special attention should be paid to the following points:

*** It is forbidden to use any flashlights and other lamps without shielding or explosion-proof glass.

*** It is forbidden to use any lengthened cable or electric furnace.

*** It is necessary to immediately repair or replace the electric apparatus and equipment if any failure occurs.

*** The cables without conduits are not allowed to be installed on the floor.

*** Cut off the power supply of the machine when going off work.

*** An electrician should be assigned to check the insulation of all the lines of electric network according to relevant regulations on heavy current, at least once a year.

4. Smoking and welding

*** Smoking is forbidden, which is applicable to all workers and staff of the enterprise as well as guests, customers, foreigners and drivers visiting the factory.

*** If the tools such as welding feed machinery or soldering lamp (flame soldering lamp) etc. are required for repair or installation, do as best as possible to arrange the work in a special workshop or on a special site.

*** If it is necessary to carry out welding or the like directly in production area or storehouse once in a while, written applications must be submitted to a related supervisor in advance for written approval. The above mentioned operations can be carried out only when special safety measures have been taken, such as laying pieces of water soaked canvas or canvas special for covering on the surrounding area and preparing fire extinguishers. After completion of the operation, the welding site and the surrounding area are to be monitored at least for 10h. The gas cutting sparks are very dangerous, for people can't see where they will fly on earth. They can cross through the narrow clearance of walls and drop downstairs or to the next rooms, or even fly off 10 m away in distance. If the sparks drop in dusts, fire accidents may occur at any time.

*** Welding is prohibited on a running conveyor. If the welding work is necessary, shut down the machine first, and then make a thorough cleaning and isolate both sides of the welding site tightly with materials like mineral wool to avoid connecting with other conveying devices, silos or tanks. If the work is to be done on the chutes or conveying pipes, it is necessary to disassemble them or divert their lower ends and seal them to avoid welding sparks entering the conveying pipes or silos.

1. Common cleaning work

*** Keeping the working site with combustible dust clean is an important condition for safe production.

*** Try not to pile bagged or bulk materials between machines.

*** In order to reduce dust emission to surrounding areas, all conveying devices, cyclone separators and dust collectors should be kept in good condition. Especially, the unsealing phenomena of pipes or top covers should be avoided.

*** In order to reduce dust explosion hazard, dust everywhere must be cleaned out frequently and effectively.

*** Keep all motors free of deposited dust.

2. Frequent inspection and maintenance

*** Regularly Check all V-belts and flat belts for driving conditions, at least once a week, so as to avoid heat generation due to skid.

*** Regularly check the safety feed machine such as speed monitor or the like, at least once a week.

*** Check and clean all the magnetic separators, stoners and sifters regularly, at least once a day.

*** In order to avoid heat generation, it is necessary to regularly check the functions of all main shafts and bearings, at least once a week, and to regularly fill up lubricating oil.

3. Electric apparatus

Regularly check the electric apparatus and articles, and special attention should be paid to the following points:

*** It is forbidden to use any flashlights and other lamps without shielding or explosion-proof glass.

*** It is forbidden to use any lengthened cable or electric furnace.

*** It is necessary to immediately repair or replace the electric apparatus and equipment if any failure occurs.

*** The cables without conduits are not allowed to be installed on the floor.

*** Cut off the power supply of the machine when going off work.

*** An electrician should be assigned to check the insulation of all the lines of electric network according to relevant regulations on heavy current, at least once a year.

4. Smoking and welding

*** Smoking is forbidden, which is applicable to all workers and staff of the enterprise as well as guests, customers, foreigners and drivers visiting the factory.

*** If the tools such as welding feed machinery or soldering lamp (flame soldering lamp) etc. are required for repair or installation, do as best as possible to arrange the work in a special workshop or on a special site.

*** If it is necessary to carry out welding or the like directly in production area or storehouse once in a while, written applications must be submitted to a related supervisor in advance for written approval. The above mentioned operations can be carried out only when special safety measures have been taken, such as laying pieces of water soaked canvas or canvas special for covering on the surrounding area and preparing fire extinguishers. After completion of the operation, the welding site and the surrounding area are to be monitored at least for 10h. The gas cutting sparks are very dangerous, for people can't see where they will fly on earth. They can cross through the narrow clearance of walls and drop downstairs or to the next rooms, or even fly off 10 m away in distance. If the sparks drop in dusts, fire accidents may occur at any time.

*** Welding is prohibited on a running conveyor. If the welding work is necessary, shut down the machine first, and then make a thorough cleaning and isolate both sides of the welding site tightly with materials like mineral wool to avoid connecting with other conveying devices, silos or tanks. If the work is to be done on the chutes or conveying pipes, it is necessary to disassemble them or divert their lower ends and seal them to avoid welding sparks entering the conveying pipes or silos.

9/19/2014

The Usage on Muyang TLMC12 Jet Filter Dust Collector

Dust concentration of dust-containing air, relative humidity, physical and chemical characters of dust such as dust size, density, adhesivity and explosive repose angle shall be known after determining to use the filtering sleeve dust collector.

Consider the filtering air speed and filtering area when selecting a dust collector. The designed filtering air speed of full series dust collectors shall be not more than 4 m/min. The filtering air speed is determined by dust characteristics and density, usually the middle/lower limit is selected; as for light and small dust particles, the filtering air speed shall be much lower, or even less than 2 m/min; the lower the filtering air speed, the higher the dust removal efficiency, however, the cost will be increased; therefore, it is important to select the filtering air speed applicable for the character of dust to obtain a better performance-price ratio. Determine the filtering area based on volume of air to be treated after determining the filtering air speed; see Table 1 for corresponding parameters to select correct dust collector model.

Normally, the feed machine is used for treating dust-containing air with a dust particle size more than 1μm; for treating dust-containing air with a dust particle size less than 1μm, please inform us when ordering, so that we can select other filter material and guide you to adjust the corresponding working parameters.

Please inform us when ordering if the dust collector will be used for central dust collecting and pneumatic conveying and the air pressure exceeds 15000Pa, so that we can adjust the corresponding structure.

It is recommended to select a dust collector with larger size or equip an additional pre-purifier when the dust concentration at the entry of the dust collector is more than 15g/m3.

Please inform us if you have any special requirements to the dust collector or you have any other ideas.

In addition, we have other feed machinery available here, you can contact anytime.

Consider the filtering air speed and filtering area when selecting a dust collector. The designed filtering air speed of full series dust collectors shall be not more than 4 m/min. The filtering air speed is determined by dust characteristics and density, usually the middle/lower limit is selected; as for light and small dust particles, the filtering air speed shall be much lower, or even less than 2 m/min; the lower the filtering air speed, the higher the dust removal efficiency, however, the cost will be increased; therefore, it is important to select the filtering air speed applicable for the character of dust to obtain a better performance-price ratio. Determine the filtering area based on volume of air to be treated after determining the filtering air speed; see Table 1 for corresponding parameters to select correct dust collector model.

Normally, the feed machine is used for treating dust-containing air with a dust particle size more than 1μm; for treating dust-containing air with a dust particle size less than 1μm, please inform us when ordering, so that we can select other filter material and guide you to adjust the corresponding working parameters.

Please inform us when ordering if the dust collector will be used for central dust collecting and pneumatic conveying and the air pressure exceeds 15000Pa, so that we can adjust the corresponding structure.

It is recommended to select a dust collector with larger size or equip an additional pre-purifier when the dust concentration at the entry of the dust collector is more than 15g/m3.

Please inform us if you have any special requirements to the dust collector or you have any other ideas.

In addition, we have other feed machinery available here, you can contact anytime.

9/11/2014

TLTSG Series Stationary Dump Dust Filter with a Sifter

Our Jet Filter Dust Collector belongs to a bag-type, internal filtering, high-pressure, reverse air jet, impulse dust collector, featured by reliable performance, high efficiency dust collecting, low discharge concentration, easy operating and maintenance, pretty appearance, compact structure and small floor area. It is applicable for dust control in industries of cereals and feed processing, feed machine, metallurgy, building materials and cement, and dust cleaning or recycling and filtering in pneumatic conveying or aspiration duct collecting in other workshop sections. It is used for improving work environment, work efficiency and product quality etc.

TLTSG Series Stationary Dump Dust Filter with a Sifter features:

***Mobile and stationary two modes, one machine one time used for several inlets.

***The TLTSG Stationary Dump Dust Filter contains dust removal device to prevent dust from escaping, improving working environment.

***The machine has advantages of low noise, low vibration,simple structure and ease of maintenance.

***The machine can crush caked powder material and feature more even filling. Wide application for manual feed inlet in industries as food milling, feed milling, sugar making.

TLTSG Series Stationary Dump Dust Filter with a Sifter features:

***Mobile and stationary two modes, one machine one time used for several inlets.

***The TLTSG Stationary Dump Dust Filter contains dust removal device to prevent dust from escaping, improving working environment.

***The machine has advantages of low noise, low vibration,simple structure and ease of maintenance.

***The machine can crush caked powder material and feature more even filling. Wide application for manual feed inlet in industries as food milling, feed milling, sugar making.

TLTSG Series Stationary Dump Dust Filter with a Sifter features:

***Mobile and stationary two modes, one machine one time used for several inlets.

***The TLTSG Stationary Dump Dust Filter contains dust removal device to prevent dust from escaping, improving working environment.

***The machine has advantages of low noise, low vibration,simple structure and ease of maintenance.

***The machine can crush caked powder material and feature more even filling. Wide application for manual feed inlet in industries as food milling, feed milling, sugar making.

TLTSG Series Stationary Dump Dust Filter with a Sifter features:

***Mobile and stationary two modes, one machine one time used for several inlets.

***The TLTSG Stationary Dump Dust Filter contains dust removal device to prevent dust from escaping, improving working environment.

***The machine has advantages of low noise, low vibration,simple structure and ease of maintenance.

***The machine can crush caked powder material and feature more even filling. Wide application for manual feed inlet in industries as food milling, feed milling, sugar making.

8/25/2014

Muyang SFJZ Vibrating Sifter

This SFJZ vibrating sifter consists of a feeding inlet, a feeding outlet, an exhaust opening, a sieve body, vibrating motors, rubber springs and a feed machine frame.

The feeding inlet is flexibly connected with a spout, and through the adjustable baffle plates the materials are distributed and then drop onto the sieve cover. Due to the obstruction of baffles for uniform distribution, the materials are further evenly spread over the first and second sieve covers for sifting. The stocks with different particle size will be discharged out of the machine via different outlets.

Working conditions

(1) Environmental conditions

① Environment temperature for normal use is within -15~+40℃;

② Relative moisture content for normal use is within 30%~85%;

③ Altitude for normal use is lower than 1000 m;

(2) Configuration conditions

① The vibrating sifter should match with the complete sets of equipments in the process;

② Configuration shall be carried out within the power supply for normal use (permissible voltage deviation ±5% and frequency deviation ±1 HZ);

③ The user must configure an over-voltage protection device for the power supply.

The feeding inlet is flexibly connected with a spout, and through the adjustable baffle plates the materials are distributed and then drop onto the sieve cover. Due to the obstruction of baffles for uniform distribution, the materials are further evenly spread over the first and second sieve covers for sifting. The stocks with different particle size will be discharged out of the machine via different outlets.

Working conditions

(1) Environmental conditions

① Environment temperature for normal use is within -15~+40℃;

② Relative moisture content for normal use is within 30%~85%;

③ Altitude for normal use is lower than 1000 m;

(2) Configuration conditions

① The vibrating sifter should match with the complete sets of equipments in the process;

② Configuration shall be carried out within the power supply for normal use (permissible voltage deviation ±5% and frequency deviation ±1 HZ);

③ The user must configure an over-voltage protection device for the power supply.

8/19/2014

Muyang SJHS Mixer Machine

Mixing is important to the quality and the feeding effectiveness of compound feed (or premix) during production. The production capacity of a feed mill usually is determined by its batching and mixing ability.

Muyang SJHS series Double-circle Paddle Mixer, designed with feed-to-food safety standard, is effective in mixing powdery ingredients (bulk density< 1kg/l) for animal feed, food and pet food. Liquid application is available.

Efficient and homogenous

Double-circle rotor contributes to fully mixing in both fast-flow zone and slow-flow zone, the mixing period is as short as 45-60s, but the homogeneity of product can be up to 97.7%.

Minimum residue

Optimized paddle-to-wall gap and fully opened discharge gates of the feed machine ensure momentary discharging, minimum residue and free of contamination.

No leakage

Assembly type seals for the discharge gates and shaft ends, good in sealing and convenient in assembly and adjustment as well as replacement operations.

User friendliness

Large access door, ease of cleaning and maintenance; Safety switch to protect personel from injury during cleaning and maintenacnce.

Muyang SJHS series Double-circle Paddle Mixer, designed with feed-to-food safety standard, is effective in mixing powdery ingredients (bulk density< 1kg/l) for animal feed, food and pet food. Liquid application is available.

Efficient and homogenous

Double-circle rotor contributes to fully mixing in both fast-flow zone and slow-flow zone, the mixing period is as short as 45-60s, but the homogeneity of product can be up to 97.7%.

Minimum residue

Optimized paddle-to-wall gap and fully opened discharge gates of the feed machine ensure momentary discharging, minimum residue and free of contamination.

No leakage

Assembly type seals for the discharge gates and shaft ends, good in sealing and convenient in assembly and adjustment as well as replacement operations.

User friendliness

Large access door, ease of cleaning and maintenance; Safety switch to protect personel from injury during cleaning and maintenacnce.

8/13/2014

Dust Discharging Device of LNGM Dust Collector

The Dust discharging device of this series

dust collector is mainly composed of a packing auger and an airlock. There are

three forms: dust discharging by a conic bunker is equipped with only an

airlock, single packing auger and double packing auger dust discharging are

equipped with one airlock and two airlocks, and the packing auger is powered by

the drive motor of the airlock. A hanging bearing is set in the middle of the

double-auger.

The impulse control instrument on the feed machine is a main control device for air jet and

dust discharging system of the dust collector, and completed with imported

digital integrated circuits, which is characterized by stability and

reliability, strong interference resistance, long service life and convenient

adjustment. Correct setting of impulse width and impulse interval is a key

factor for normal work of the dust removal system.

Technical performance: 1. Adjusting scope

of impulse width: 0.03s ~ 0.3s; 2. Adjusting scope of impulse interval: 3s

~60s; 3. Output voltage: AC 24V; output current: 0.8 A ~1A; 4. Output circuit:

1~60 for option or matched with quantity of the solenoid valves for the dust

collector.

8/05/2014

CP Group and Muyang Enjoy a long, Special Ties

On November 1, 2010, Mr. Dhanin Chearavanont, Chairman of CP Group, met with visiting Muyang Chairman Li Minyue in Bangkok. Both sides held an in-depth talk on the development of standardized feed processing technology and the long-term cooperation relationship between CP and Muyang.

CP Group is the largest feed machine manufacturer in the world while Muyang is the global leading integrated solution supplier in feed industry. The many years’ cooperation relationship has benefited both sides’ rapid expansion in China and other parts of the world.

Mr. Chearavanont gave highly credit for the professional, rapid reaction and characteristic service that brought by Muyang and believed that the two groups will be in a more solid relationship in the future. Mr. Li Minyue owed the present achievements of Muyang to the on-going support of many key customers like CP Group, and said that Muyang will always entertain excellent contacts with all important customers with the "key customer strategy" and "internationalization strategy" in mind and commit itself to creating more value for the customers worldwide.

CP Group is the largest feed machine manufacturer in the world while Muyang is the global leading integrated solution supplier in feed industry. The many years’ cooperation relationship has benefited both sides’ rapid expansion in China and other parts of the world.

Mr. Chearavanont gave highly credit for the professional, rapid reaction and characteristic service that brought by Muyang and believed that the two groups will be in a more solid relationship in the future. Mr. Li Minyue owed the present achievements of Muyang to the on-going support of many key customers like CP Group, and said that Muyang will always entertain excellent contacts with all important customers with the "key customer strategy" and "internationalization strategy" in mind and commit itself to creating more value for the customers worldwide.

7/28/2014

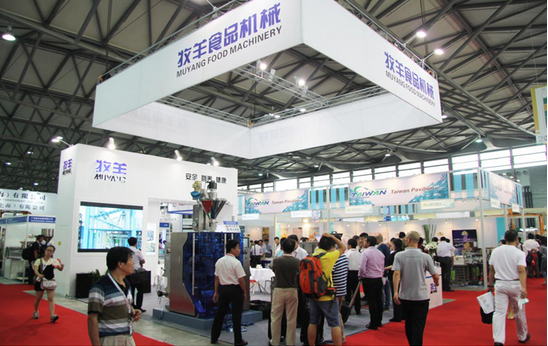

Muyang Food Machinery debuts at PorPak China 2014

On July 16, PorPak China 2014 was take place at New International Expo Centre(SNICE) in Shanghai, China. Muyang Feed Machinery attend this Expo.

PorPak China is China's premier trade exhibition for Packaging and processing technologies. More than 600 company,from 33 countries and regions, attend this expo.

In the exhibition, our posted Food Mixer and MCPB250 automatic vertical packaging machine attracted lots of visitors. Our colleagues not only patiently introduced our products, but also answered questions of many visitors. It impressed them and help us earn many further business chances.

The article is from : http://www.machineryshops.com/news/view/332.html?type=news

PorPak China is China's premier trade exhibition for Packaging and processing technologies. More than 600 company,from 33 countries and regions, attend this expo.

In the exhibition, our posted Food Mixer and MCPB250 automatic vertical packaging machine attracted lots of visitors. Our colleagues not only patiently introduced our products, but also answered questions of many visitors. It impressed them and help us earn many further business chances.

The article is from : http://www.machineryshops.com/news/view/332.html?type=news

7/21/2014

Structural readjustment: Muyang R&D Institute formed

***Structural readjustment: Muyang R&D Institute formed***

Muyang announced the formally establishment of the Muyang R&D Institute on March 11 after restructuring all research resources group-wide. Muyang CEO, Mr. Chen Zhengjun, concurrently serves as the head of Muyang R&D Institute.

The new R&D Institute consists of an innovation center and several technology sub-centers. Engineers in the technology sub-center of each business division will focus on providing prompt customized product and project solutions that catering to the current customers’ demand, while researchers in the innovation center will dedicate themselves to develop cutting-edge products and technologies that keep customers leading in the industry for 3~5 years in the future.

"The restructuring is to further extend our technological leadership, make it more competitive and better organized for our present business development and future strategy of growing into a leading global integrated solution provider for the Farm-Food value chain." Mr. Chen said.

Three percent of the our total sales will be spent on research and development. Activities will emphasize on energyefficiency, smart production and cost-saving.

Muyang announced the formally establishment of the Muyang R&D Institute on March 11 after restructuring all research resources group-wide. Muyang CEO, Mr. Chen Zhengjun, concurrently serves as the head of Muyang R&D Institute.

The new R&D Institute consists of an innovation center and several technology sub-centers. Engineers in the technology sub-center of each business division will focus on providing prompt customized product and project solutions that catering to the current customers’ demand, while researchers in the innovation center will dedicate themselves to develop cutting-edge products and technologies that keep customers leading in the industry for 3~5 years in the future.

"The restructuring is to further extend our technological leadership, make it more competitive and better organized for our present business development and future strategy of growing into a leading global integrated solution provider for the Farm-Food value chain." Mr. Chen said.

Three percent of the our total sales will be spent on research and development. Activities will emphasize on energyefficiency, smart production and cost-saving.

7/15/2014

STHJ Series A Type Paddle Molasses Mixer

STHJ Series A Type Paddle Molasses Mixer consists of a rotor, a machine body, a bearing support, big and small belt pulleys, and guard shield.

The power is transferred from the motor to the rotor via sprocket. The molasses is blown into the mixer machine by steam. The paddles are regularly staggered on the rotor along axial and circumferential directions in a certain angle to the rotor, so that a helical surface is formed between the paddles. When working, the rotor brings the feed to roll over and meantime push them to the discharging outlet.

Machine body

The feed machinery body is composed of a trough, ring flanges, wall plates, a clearing gate, a feeding inlet and a discharging outlet etc. It is dismountable, and easy for the installation and replacement of the rotor, and a large clearing gate is convenient for cleaning of the rotor as well as replacement and adjustment of the paddles.

Addition of molasses

Molasses is blown in by steam via molasses adding pipes. The heating temperature of the molasses mixture is 32℃~38℃, and its viscosity should be less than 200 CP. The steam temperature is 130℃ and the pressure is 0.3MPa.

Protective device

In order to prevent any accident in work of machine, the cleaning gate is equipped with an interlocking safety device, to ensure that the motor cannot be started when the cleaning gate is open.

The power is transferred from the motor to the rotor via sprocket. The molasses is blown into the mixer machine by steam. The paddles are regularly staggered on the rotor along axial and circumferential directions in a certain angle to the rotor, so that a helical surface is formed between the paddles. When working, the rotor brings the feed to roll over and meantime push them to the discharging outlet.

Machine body

The feed machinery body is composed of a trough, ring flanges, wall plates, a clearing gate, a feeding inlet and a discharging outlet etc. It is dismountable, and easy for the installation and replacement of the rotor, and a large clearing gate is convenient for cleaning of the rotor as well as replacement and adjustment of the paddles.

Addition of molasses

Molasses is blown in by steam via molasses adding pipes. The heating temperature of the molasses mixture is 32℃~38℃, and its viscosity should be less than 200 CP. The steam temperature is 130℃ and the pressure is 0.3MPa.

Protective device

In order to prevent any accident in work of machine, the cleaning gate is equipped with an interlocking safety device, to ensure that the motor cannot be started when the cleaning gate is open.

7/09/2014

FAMSUN Animal Farming: Side with farmers to feed the future

Animal Farming is one of the most vital businesses of FAMSUN. The young unit has steady served the industry since 2009 thanks to the acquisition of China Famous Sichuan Ningshi Animal Husbandry Equipment Co., the expansion of research and production base in Changzhou, China, and the establishment of solid partnerships withtop suppliers worldwide.

Based on strong technical support and rich experience, with powerful engineering resource of its parent company, FAMSUN Animal Farming now is able to provide complete solutions from customized design to excellent manufacture, unloaded purchase, safe and qualified construction, as well as thorough and meticulous aftersales service.

The stand-alone machine products and complete solutions include:

Poultry farm system: breeding houses / flat or cage raising system / feeding system /drinking system / egg collecting system / house conditioning and control system / farm climate control system

Pig farm system: raising house / penning system / feeding system /automation system / farm environmental system

Expanded business: procurement of feed and feed ingredients, egg incubator, and slaughtering system.

Based on strong technical support and rich experience, with powerful engineering resource of its parent company, FAMSUN Animal Farming now is able to provide complete solutions from customized design to excellent manufacture, unloaded purchase, safe and qualified construction, as well as thorough and meticulous aftersales service.

The stand-alone machine products and complete solutions include:

Poultry farm system: breeding houses / flat or cage raising system / feeding system /drinking system / egg collecting system / house conditioning and control system / farm climate control system

Pig farm system: raising house / penning system / feeding system /automation system / farm environmental system

Expanded business: procurement of feed and feed ingredients, egg incubator, and slaughtering system.

6/23/2014

Grinding Hammer Mill

This feed machine from the host, auxiliary equipment, electric con- trol box of three parts, with a winnowing, no screen, no network, a variety of properties and uniform particle size, the production pro- cess is continuous. Crushing operations in the host machine is not heating up, can crush all kinds of heat sensitive materials. The overall performance has reached international advanced level, it is widely used in pharmaceutical, chemical, food (example: traditional Chinese medicine. Food. Chemical. Health care. Root class. Diam- eter class. Corn, rice, chili, pepper, oil and wheat, soybean, garlic , star anise, cinnamon, dehydrated vegetables, hawthorn, ginger, garlic, sugar. sweeteners. grains, dried small shrimps, pumpkin powder, spices) and other industrial materials crushed.

The grinding machine is a vertical shaft reflective micro crusher, can finish at the same time fine crushing and micro powder sorting the two processes. It consists of the body, frame, feeding device, crushing equipment, discharge tube, transmission device and motor and other components, supporting the host, precipitator, high-pressure centrifu- gal fan, shut the wind instrument, a whirlwind collector and electric control cabinet and other components of a complete set of air turbine micro powder units. Don't stop in the case, can be arbitrary regulation size. Products of granularity, fine degrees can reach up to 10-5 um, it has since cooling function. (example: chemical, Chinese traditional medicine, and root kind, diameter classes, corn, rice, chili, pepper, YouMai, soybean, soybean meal, garlic, octagon, cinnamon, dehydrated vegetables, hawthorn, dry ginger, garlic piece, white sugar, saccharin, food, shrimp skin, pumpkin.

The grinding machine is a vertical shaft reflective micro crusher, can finish at the same time fine crushing and micro powder sorting the two processes. It consists of the body, frame, feeding device, crushing equipment, discharge tube, transmission device and motor and other components, supporting the host, precipitator, high-pressure centrifu- gal fan, shut the wind instrument, a whirlwind collector and electric control cabinet and other components of a complete set of air turbine micro powder units. Don't stop in the case, can be arbitrary regulation size. Products of granularity, fine degrees can reach up to 10-5 um, it has since cooling function. (example: chemical, Chinese traditional medicine, and root kind, diameter classes, corn, rice, chili, pepper, YouMai, soybean, soybean meal, garlic, octagon, cinnamon, dehydrated vegetables, hawthorn, dry ginger, garlic piece, white sugar, saccharin, food, shrimp skin, pumpkin.

6/18/2014

Muyang Changes Brand Name to FAMSUN

Muyang Co.,Ltd. recently announced changing its brand name from Muyang to FAMSUN starting May 2014.This move is prompted by the idea of better illustrating the company's business and the farm-to-table industry chain it serves. It is consistent with Muyang's global strategy and its aim of becoming an integrated solution provider in the agro-industry.

FAMSUN originates from "famous, farm, family, sun and union"; it implies Muyang development concept and vision, which is to build a green and healthy supply chain from farm to table together with its customers and to convert traditional agriculture into a modern, profitable and sustainable business with its integrated solutions in feed machinery manufacturing, grain milling, grain handling and storage, food processing, as well as industrial automation.

The creative design of the FAMSUN logo features a beveled letter "F"; a curvy letter "A"; a stretching letter "S" and a friendly letter "U". It will be the only signage representing Muyang's business, products, service and solutions. Meanwhile,the company will continue to operate in its current structure, provide follow-up service based on relevant agreement, and its business contacts will remain unchanged.

FAMSUN will make its public debut at the 12th China Animal Husbandry Expo between May 18th and 20th in Qingdao,China and VIV Europe 2014 between May 20th and 22nd in Utrecht, Netherlands.

FAMSUN originates from "famous, farm, family, sun and union"; it implies Muyang development concept and vision, which is to build a green and healthy supply chain from farm to table together with its customers and to convert traditional agriculture into a modern, profitable and sustainable business with its integrated solutions in feed machinery manufacturing, grain milling, grain handling and storage, food processing, as well as industrial automation.

The creative design of the FAMSUN logo features a beveled letter "F"; a curvy letter "A"; a stretching letter "S" and a friendly letter "U". It will be the only signage representing Muyang's business, products, service and solutions. Meanwhile,the company will continue to operate in its current structure, provide follow-up service based on relevant agreement, and its business contacts will remain unchanged.

FAMSUN will make its public debut at the 12th China Animal Husbandry Expo between May 18th and 20th in Qingdao,China and VIV Europe 2014 between May 20th and 22nd in Utrecht, Netherlands.

6/09/2014

Muyang Accelerate the Pace of Internationalization

Recently, Muyang, in the 12th Livestock Exposition, released a new brand identity: FAMSUN. From MUYANG to FAMSUN, the domestic feed machinery industry leading brand was accelerating the pace of internationalization. President Fan Tianming of Muyang said it would continue through technological innovation and industrial chain extension to make FAMSUN into a world-class brand.

Behind the releasing the new brand, Muyang indicated the strategic intent to expand overseas market, and now Muyang products already covered more than one hundred countries and regions worldwide, extending the service to whole industry chain.

It is understood that Muyang continued innovation in product development, fully tapped the potential of alternative raw materials. Previous extruder raw protein content was very high, and we should use fish meal to produce. Muyang now developed a new extruder, other materials can be processed like cassava. Previous extruder was difficult to be used in the cassava protein, while the new device was able to destroy the peptide bond absorption, and it can be utilized as the raw material. With this new equipment, feather meal can be used as feed ingredients. There are a lot of feather protein, but due to the peptide bond was very long, the animals can not properly digest. The new device may be converted to a protein in general, so that the animal can be absorbed. By reducing the requirements for the raw material processing equipment, the use of raw materials for production substitutability, greatly reduce the production cost of feed.

In recent years, independent research and development of core machinery by Muyang have passed through the EU certification, capturing the stringent EU product standards. Today, Muyang's products have been sold to 102 countries and territories worldwide.

Currently, both the feed industry and feed equipment manufacturing, are facing with large-scale, intelligent development trend of the industry for feed production machinery and equipment suppliers, research and service capacity of a test. Feed machine manufacturing enterprises need to provide more large-scale, intelligent feed processing equipment to meet customer demand for the efficient production of large quantities of high-quality feed products.

Muyang's new brand strategy is designed to scale and intelligent development, and through the exchange of knowledge, skills, experience sharing to help customers to create system solutions on "from pastoral to table" around the world and meet the challenges of food security and sustainable development.

Behind the releasing the new brand, Muyang indicated the strategic intent to expand overseas market, and now Muyang products already covered more than one hundred countries and regions worldwide, extending the service to whole industry chain.

It is understood that Muyang continued innovation in product development, fully tapped the potential of alternative raw materials. Previous extruder raw protein content was very high, and we should use fish meal to produce. Muyang now developed a new extruder, other materials can be processed like cassava. Previous extruder was difficult to be used in the cassava protein, while the new device was able to destroy the peptide bond absorption, and it can be utilized as the raw material. With this new equipment, feather meal can be used as feed ingredients. There are a lot of feather protein, but due to the peptide bond was very long, the animals can not properly digest. The new device may be converted to a protein in general, so that the animal can be absorbed. By reducing the requirements for the raw material processing equipment, the use of raw materials for production substitutability, greatly reduce the production cost of feed.

In recent years, independent research and development of core machinery by Muyang have passed through the EU certification, capturing the stringent EU product standards. Today, Muyang's products have been sold to 102 countries and territories worldwide.

Currently, both the feed industry and feed equipment manufacturing, are facing with large-scale, intelligent development trend of the industry for feed production machinery and equipment suppliers, research and service capacity of a test. Feed machine manufacturing enterprises need to provide more large-scale, intelligent feed processing equipment to meet customer demand for the efficient production of large quantities of high-quality feed products.

Muyang's new brand strategy is designed to scale and intelligent development, and through the exchange of knowledge, skills, experience sharing to help customers to create system solutions on "from pastoral to table" around the world and meet the challenges of food security and sustainable development.

6/04/2014

Some Key Points on Improving Performance of Pellet Mill

In the production process of high-quality feed, the quality of feed particles determines the pelleting process, and in order to improve the quality of feed grain, we should pay attention to the following points.

Feed formulation generally includes a high cereal content and a low fiber content, such as poultry feed, and pig feed, no other natural additives, except when wheat added. While these recipes require high quality steam environment in order to obtain high-quality feed.

When oil spray feed processing is an important part, it can improve the quality of feed, feeding improve palatability, and to improve the nutritional value of feed. In the granulation money added fat will reduce the particle mass, fat are generally added after granulation. Usually fat coating requires specialized equipment and high cost. Muyang pellet mill feed machinery outside the ring mold sprayed liquid, not only can be used for animal feed pelleting, but also widely used in food, oil, chemical and other industries.

The correct size of the pores on the particles contributes to the production and high quality of the feed particles must remain a standard size. Granulated particles of different sizes will affect the performance or the need to adjust the hammer die pressing surface of the roller mill. Uniform particle size of the particles will increase the rate of fracture, leading to breakage of the particles, while increasing the powder.

Steam atmosphere is very important to high cereal content of the feed, such as poultry feed, and pig feed. This formulation of the feed to kill bacteria and gelatinized starch, in the steam atmosphere needed to maintain about 45-60 seconds, the temperature of the steam is probably controlled 85-90 ℃. If the feed machine contains low grain ingredients, but with a high fiber content, it does not require such a long time modulation. If there was added molasses, then to increase the speed of the modulator to accomplish good mixing and therefore also reduces the temperature modulation. Feed formula contains high sugar and whey powder, such as suckling pig feed, almost without too much can be quenched with sticky characteristics of these ingredients. The same applies to the feed containing high urea component.

Feed formulation generally includes a high cereal content and a low fiber content, such as poultry feed, and pig feed, no other natural additives, except when wheat added. While these recipes require high quality steam environment in order to obtain high-quality feed.

When oil spray feed processing is an important part, it can improve the quality of feed, feeding improve palatability, and to improve the nutritional value of feed. In the granulation money added fat will reduce the particle mass, fat are generally added after granulation. Usually fat coating requires specialized equipment and high cost. Muyang pellet mill feed machinery outside the ring mold sprayed liquid, not only can be used for animal feed pelleting, but also widely used in food, oil, chemical and other industries.

The correct size of the pores on the particles contributes to the production and high quality of the feed particles must remain a standard size. Granulated particles of different sizes will affect the performance or the need to adjust the hammer die pressing surface of the roller mill. Uniform particle size of the particles will increase the rate of fracture, leading to breakage of the particles, while increasing the powder.

Steam atmosphere is very important to high cereal content of the feed, such as poultry feed, and pig feed. This formulation of the feed to kill bacteria and gelatinized starch, in the steam atmosphere needed to maintain about 45-60 seconds, the temperature of the steam is probably controlled 85-90 ℃. If the feed machine contains low grain ingredients, but with a high fiber content, it does not require such a long time modulation. If there was added molasses, then to increase the speed of the modulator to accomplish good mixing and therefore also reduces the temperature modulation. Feed formula contains high sugar and whey powder, such as suckling pig feed, almost without too much can be quenched with sticky characteristics of these ingredients. The same applies to the feed containing high urea component.

5/28/2014

Original From Europe, Rooted in China

Original From Europe, Rooted in China

--- Muyang Pellet Technology Achievements

Feed particles forming technology is the basis of modern feed industry, and the core concepts on nutritional balance and livestock feeding efficiency are embodied in the little dolphin feed particles.

The forming technology based on ring die pellet mill is a most popular feed processing method and its contribution to the total output of China's feed industry ratio is over 50%. Granulation technology and its application capabilities, often on behalf of a national feed industry and the technical level of feed outfits. Muyang is the one of the earliest manufactures who put ring die pellet technology and equipment applyto one feed machinery.

Adhering to the principle of "high quality, high efficiency", Muyang positively contacted with the European feed machinery manufacturer famous British UMT company as early as the 1990s, and in 1995, they created a successful partnership, successfully introduced the world at that time technology leadership in the ring die pellet models. And the following year in the domestic market Muyang launched "Muyang-UMT ring die pellet mill" leading the industrialization of China's feed industry enter the era of rapid development.

More than ten years, the degree of marketization of China's feed industry continues to improve, and in a competitive process, the use of feed and processing equipment for the deepening of understanding and use has gradually formed a unique production philosophy and technical point of view, establishing and improving the conditions of our country to feed industrial system.

Granulators developers hard pellet production technology for long-term tracking studies conducted after summarizes the feed production mode, the device application scenarios, such as the user experience first-hand the technical and market information for the current market share of the largest animal feed system granulator proposed a "specialized, high efficiency," the overall design goal, established on the basis of a clear technical performance indicators, and to project.

After two years of technical pre-research and product design, under the protection of a complete project management system in 2010, Muyang successfully launched of the "TW" series dedicated animal feed pellet mill whose capacity power units enhance the contribution of 20% above insteading of the previous generation models.

transmission structure, repression parameters core technology has broken the original European technology. Applicable, efficient production is the feed mill managers and operations staff give their assessment TW granulators.

Products are from the market and also serve market. Successful products must be based on market’s research and rigorous design control. Muyang new generation of TW Series pellet mill have occupied more than 80% of sales than similar machines, which expected to not only meet the feed manufacturers, but also to create greater economic benefits for Muyang itself.

The forming technology based on ring die pellet mill is a most popular feed processing method and its contribution to the total output of China's feed industry ratio is over 50%. Granulation technology and its application capabilities, often on behalf of a national feed industry and the technical level of feed outfits. Muyang is the one of the earliest manufactures who put ring die pellet technology and equipment applyto one feed machinery.

Adhering to the principle of "high quality, high efficiency", Muyang positively contacted with the European feed machinery manufacturer famous British UMT company as early as the 1990s, and in 1995, they created a successful partnership, successfully introduced the world at that time technology leadership in the ring die pellet models. And the following year in the domestic market Muyang launched "Muyang-UMT ring die pellet mill" leading the industrialization of China's feed industry enter the era of rapid development.

More than ten years, the degree of marketization of China's feed industry continues to improve, and in a competitive process, the use of feed and processing equipment for the deepening of understanding and use has gradually formed a unique production philosophy and technical point of view, establishing and improving the conditions of our country to feed industrial system.

Granulators developers hard pellet production technology for long-term tracking studies conducted after summarizes the feed production mode, the device application scenarios, such as the user experience first-hand the technical and market information for the current market share of the largest animal feed system granulator proposed a "specialized, high efficiency," the overall design goal, established on the basis of a clear technical performance indicators, and to project.

After two years of technical pre-research and product design, under the protection of a complete project management system in 2010, Muyang successfully launched of the "TW" series dedicated animal feed pellet mill whose capacity power units enhance the contribution of 20% above insteading of the previous generation models.

transmission structure, repression parameters core technology has broken the original European technology. Applicable, efficient production is the feed mill managers and operations staff give their assessment TW granulators.

Products are from the market and also serve market. Successful products must be based on market’s research and rigorous design control. Muyang new generation of TW Series pellet mill have occupied more than 80% of sales than similar machines, which expected to not only meet the feed manufacturers, but also to create greater economic benefits for Muyang itself.

5/20/2014

Tips to Choose Hammer Mill

With the development of the grinder line industry, an endless stream of various types of feed machinery, but no matter how the mill type of change, you still should choose your suitable one. Blow I summarize five tips which can help you how to choose right one:

1. An experiment with a grinder: the advantages of various materials have good crushing effect, especially pearls, chemical raw materials, minerals and most traditional Chinese medicine, the built-in screen thickness adjustable; drawback is that the feed size should not is too large, the output is very small, only suitable for experimental sample preparation crushing.

2. Winnowing Chinese medicine grinder: Advantages of traditional Chinese medicine for a variety of nature (including fiber, a bit of fats and oils, and a bit viscous classes), are ideal food crushing effect, the fineness of similar products in the best, up to 200 mesh, work long hours the body should not be fever, crushing most satisfactory models of Chinese medicine the best customer reaction; drawback is that the crushed material is completed there will be a small amount of residue can not be crushed.

3. The herbal medicine pulverizer group: addition winnowing the advantages of Chinese medicine grinding machine using high-quality stainless steel, meet the GMP standard to meet production needs.

4. Low noise shredder: the advantages of lower noise at work, to meet the health standard, built-in screen thickness adjustable ideal crushing effect of the pearls, chemical raw materials, mineral, and the majority of Chinese medicine; drawback is easy to heat the body, The working time is not too long, not a bit of fats and oils and a bit of sticky material crushed.

5. Small high-speed grinder: Advantages easy to use, grinding speed, drugs lossless, pearls, chemical raw materials, mineral, and the majority of Chinese medicine ideal crushing effect; drawback is that some of the material grinding fineness uneven, is not suitable for The large doses processing.

1. An experiment with a grinder: the advantages of various materials have good crushing effect, especially pearls, chemical raw materials, minerals and most traditional Chinese medicine, the built-in screen thickness adjustable; drawback is that the feed size should not is too large, the output is very small, only suitable for experimental sample preparation crushing.

2. Winnowing Chinese medicine grinder: Advantages of traditional Chinese medicine for a variety of nature (including fiber, a bit of fats and oils, and a bit viscous classes), are ideal food crushing effect, the fineness of similar products in the best, up to 200 mesh, work long hours the body should not be fever, crushing most satisfactory models of Chinese medicine the best customer reaction; drawback is that the crushed material is completed there will be a small amount of residue can not be crushed.

3. The herbal medicine pulverizer group: addition winnowing the advantages of Chinese medicine grinding machine using high-quality stainless steel, meet the GMP standard to meet production needs.

4. Low noise shredder: the advantages of lower noise at work, to meet the health standard, built-in screen thickness adjustable ideal crushing effect of the pearls, chemical raw materials, mineral, and the majority of Chinese medicine; drawback is easy to heat the body, The working time is not too long, not a bit of fats and oils and a bit of sticky material crushed.

5. Small high-speed grinder: Advantages easy to use, grinding speed, drugs lossless, pearls, chemical raw materials, mineral, and the majority of Chinese medicine ideal crushing effect; drawback is that some of the material grinding fineness uneven, is not suitable for The large doses processing.

5/14/2014

SCQZ Series Conical Drum Powder Precleaner

SCQZ series conical drum powder pre-cleaner (finished product screener) is mainly used for pre-cleaning powdery auxiliary materials in compound feed machinery. It can effectively break or remove the agglomerated blocks as well as large impurities such as straw, hemp rope, sheet paper, stone block and etc., so as to protect the subsequent machines and equipments in the process system from damage. This machine can also be applied after mixing process to sift and remove the caking bock from mixed mash, so as to ensure the quality of compound feed.

Product features

(1) This fine material conic pre-cleaner is characterized by high output, good cleaning effect, low power consumption, simple structure, small floor area and etc.

(2) The equipment is complete with an access door, which is convenient for routine repair and maintenance, as well as for replacement of the sieve drum.

(3) Appropriate sieve apertures can be selected as per the property of material, so as to get the optimum separation effect.

Product features

(1) This fine material conic pre-cleaner is characterized by high output, good cleaning effect, low power consumption, simple structure, small floor area and etc.

(2) The equipment is complete with an access door, which is convenient for routine repair and maintenance, as well as for replacement of the sieve drum.

(3) Appropriate sieve apertures can be selected as per the property of material, so as to get the optimum separation effect.

5/04/2014

How to Choose Wood Pellet Mill Manufacturers

Wood pellet, with its unique advantages of clean, renewable and recycling, are gradually stepping into our daily life which used for heating of homeowners and industrial production. Thus there rises a series of questions that where to buy high quality wood pellet mill, and how to choose wood pellet mill suppliers among so many manufacturers. Here are some reasonable suggestions for you to locate your own satisfied and reliable suppliers.

1. No matter you want to buy your wood pellet making machine from which manufacturer, remember that quality comes first. Good biomass pellet mill manufacturer features providing high quality pellet mills and cushy maintenance.

2. You choose one company as your partner because it can respond in time when you need help. The after sale service of one company must be connected easily through a phone call or an email to supply their technical backup for their customers.