If you have got Muyang mixing machine, you would notice some tips when you operate it. Following are some basic specifications:

(1) Material characteristics

Particle size of materials: Length of edge shall be less than 10mm

Bulk density: 0.15~0.8 t/m3

Total liquid addition: less than 3% among which sticky liquid such as molasses: less than 1%

(2) Environmental conditions

① Ambient temperature range (-10~+40℃)

② Relative humidity range: 30%~85%

③ Altitude: Less than 1000m

④ Temperature range for normal transportation is:-25~55℃

⑤ Air supply for normal use is above 0.6Mpa

⑥ Electric supply for normal use: AC380V

Note: if the actual condition fails to accord with the environment condition ①, the temperature shall be adjusted properly. If it fails to accord with conditions ② and ③, a speed reducing motor shall be customized. If it fails to accord with condition ⑥, please refer to the motor nameplate.

(3) Configuration conditions

① The paddle mixer should match the equipments before and after it in process flow.

② Configuration shall be carried out within the power supply for normal use (permissible voltage deviation ±5% and frequency deviation ±1%).

③ The user must configure an over-voltage protection device for the power supply.

(4) Noise testing during normal production.

8/29/2013

8/28/2013

Muyang SJHS0.5B Double-circle Paddle Mixer

Environment conditions

In order to operate this paddle mixer safely, please install it according to following operating conditions.

(1)Please install this equipment indoors according to following conditions:

Ambient temperature range (-10~+40°C)

Relative humidity range: 30%~85%

Altitude: less than 1000m

Guarantee indoor cleaning and ventilation

Guarantee that the equipment is far away from the corrosive gas, inflammable and explosive gas as well as steam

(2)Power source: as for Voltage and Frequency, please refer to the nameplate; pressure ≧0.6Mpa.

(3)For easy use, operation and maintenance, please check this equipment and reserve enough space for it.

(4)Please place the mixing machine horizontally.

(5)The vibration to be borne under effects of many complicated environments may not exceed 12 mm∙s.

Description of warning marks

(1)In order to well understand this operation Manual, the safety warning marks are divided into following kinds.

(2)These warning marks have been worked out according to the operating regulations and safety attention points for this equipment. In order to avoid dangerous accidents, this Operation Manual also includes concrete preventive measures. Please operate this equipment according to the instructions based on sufficient understanding of warning marks.

Description of safety marks

(1)Relevant safety marks are pasted on different corresponding positions of this feed mixer, which are property dangerous to personal safety.

(2)All the safety marks are indicated. Please carefully understand and install, adjust, operate, maintain and inspect this equipment.

(3)Please place these safety marks near the equipment.

(4)When these safety marks have fallen off or been damaged, please replace them with new marks.

(5)If you want to order new marks, please contact our company.

In order to operate this paddle mixer safely, please install it according to following operating conditions.

(1)Please install this equipment indoors according to following conditions:

Ambient temperature range (-10~+40°C)

Relative humidity range: 30%~85%

Altitude: less than 1000m

Guarantee indoor cleaning and ventilation

Guarantee that the equipment is far away from the corrosive gas, inflammable and explosive gas as well as steam

(2)Power source: as for Voltage and Frequency, please refer to the nameplate; pressure ≧0.6Mpa.

(3)For easy use, operation and maintenance, please check this equipment and reserve enough space for it.

(4)Please place the mixing machine horizontally.

(5)The vibration to be borne under effects of many complicated environments may not exceed 12 mm∙s.

Description of warning marks

(1)In order to well understand this operation Manual, the safety warning marks are divided into following kinds.

(2)These warning marks have been worked out according to the operating regulations and safety attention points for this equipment. In order to avoid dangerous accidents, this Operation Manual also includes concrete preventive measures. Please operate this equipment according to the instructions based on sufficient understanding of warning marks.

Description of safety marks

(1)Relevant safety marks are pasted on different corresponding positions of this feed mixer, which are property dangerous to personal safety.

(2)All the safety marks are indicated. Please carefully understand and install, adjust, operate, maintain and inspect this equipment.

(3)Please place these safety marks near the equipment.

(4)When these safety marks have fallen off or been damaged, please replace them with new marks.

(5)If you want to order new marks, please contact our company.

8/25/2013

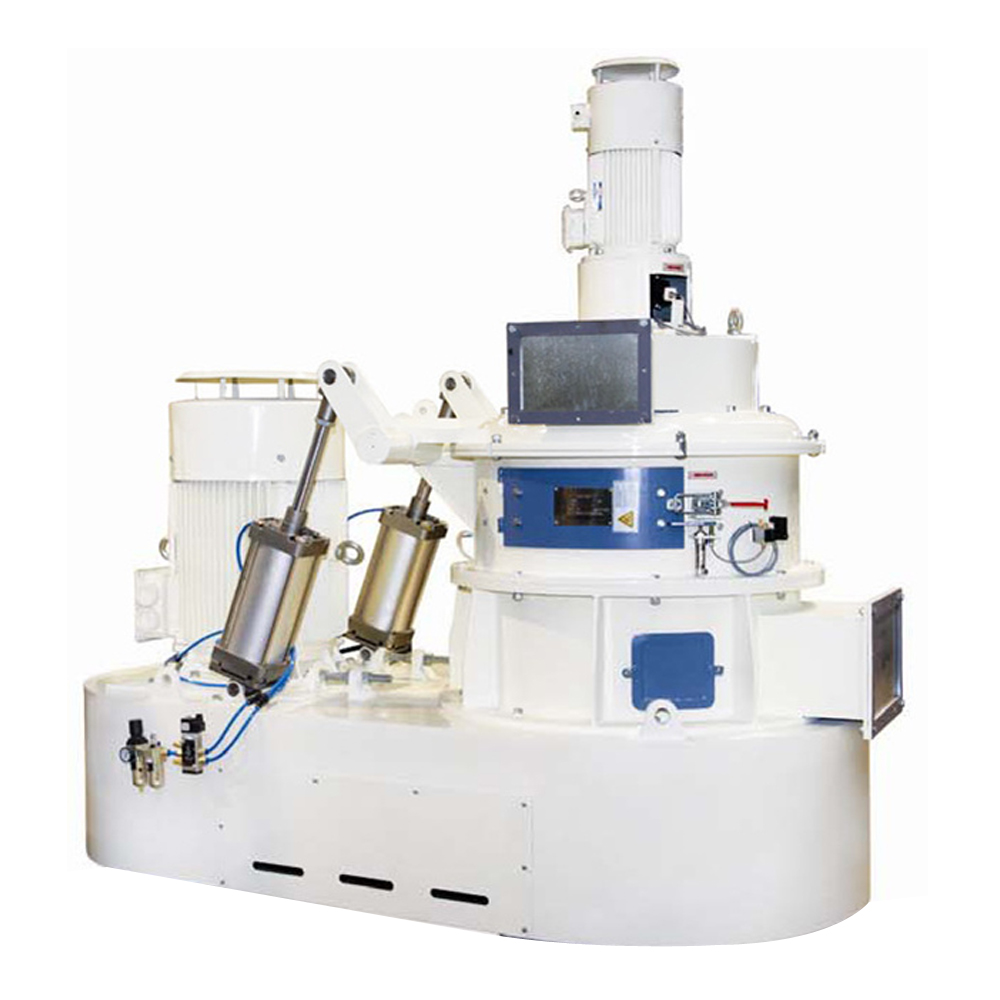

Muyang MPJH Series Food Mixer

MPJH Series Double-Circle Paddle Mixers are widely used for mixing powdery, granular, flaky, lumpish, sticky and miscellaneous materials in food industry, and also for drying and cooling different materials.

Features

1. The rotor adopted is in our unique proprietary double-circle structure, which is characterized by its short mixing period and high mixing homogeneity, for common materials the mixing homogeneity is CV≤5% or even up to 2%~3% within 45s~60s. So, the mixing time is shortened and the production efficiency of the feed mill can be greatly improved;

2. Large variable range of filling factor: 0.4~1, applicable for mixing the materials with different specific gravity and granularity etc. in food industry;

3. Our unique proprietary technology for sealing is adopted for shaft-end sealing mechanism, featuring reliable sealing performance, long service life and free of leakage;

4. Fast discharge and little residues: the discharge gate on the mixing machinery is in a bomb-type full-bottom double-leaf structure, so the discharging is fast with little residues;

5. For the sealing mechanism of discharge gate, our unique patented technology of air-sac sealing is used, which can make up the defect of gate body deformation, and it is reliable for sealing and free of leakage;

Operating conditions

1. Operating under normal temperature and pressure;

2. The front and rear corollary equipments for mixing machine should be matched in technology.

Features

1. The rotor adopted is in our unique proprietary double-circle structure, which is characterized by its short mixing period and high mixing homogeneity, for common materials the mixing homogeneity is CV≤5% or even up to 2%~3% within 45s~60s. So, the mixing time is shortened and the production efficiency of the feed mill can be greatly improved;

2. Large variable range of filling factor: 0.4~1, applicable for mixing the materials with different specific gravity and granularity etc. in food industry;

3. Our unique proprietary technology for sealing is adopted for shaft-end sealing mechanism, featuring reliable sealing performance, long service life and free of leakage;

4. Fast discharge and little residues: the discharge gate on the mixing machinery is in a bomb-type full-bottom double-leaf structure, so the discharging is fast with little residues;

5. For the sealing mechanism of discharge gate, our unique patented technology of air-sac sealing is used, which can make up the defect of gate body deformation, and it is reliable for sealing and free of leakage;

Operating conditions

1. Operating under normal temperature and pressure;

2. The front and rear corollary equipments for mixing machine should be matched in technology.

8/21/2013

Personal Protection: Countermeasures against Accidents

1. All the mechanical equipments produced by Jiangsu Muyang Group are equipped with safety devices, which are consistent with modern technical level and universally effective safety rules prior to ex works, so that the customers can use the machines in accordance with the regulations.

2. Enterprises are obligate to execute following regulations to guarantee operators' safety.

3. The shield caps for belts and chains must be mounted and closed at any moment. It is very dangerous to personal safety, if they are open or disassembled. This point is also applicable for the preventive device of manipulator.

4. The safety limit switches, interlinking cylinders, revolution monitors and solenoid valves or locking electromagnets of the door interlocking devices should always be kept in good order. The safety limit switch may not be overlapped or discarded.

5. The grating cover plate on the grinding machine, grid bar or guard grating are usually installed and delivered together with the machine. They can only be disassembled with tools. And the machines with such kind of devices can never put into work until the above-said devices have been properly installed.

6. The driving motor must be switched off completely when carrying out inspection, commissioning, repair and maintenance. This can be realized through a full-phase separating and lockable switch installed near the machine or on the operation desk and control panel on the site. It is not enough only to screw off the fuse wire!

7. If the grinding machines need other energy like pneumatic, hydraulic, steam and hot water energy, it is necessary to cut off their energy supply or turn off the switch, and eliminate the pressure in the internal pipeline system of the machine.

8. As for handling heated or cooled parts and components of the machine, especial care should still be taken for the danger of burning possibility.

9. If you have pressed the emergency stop switch to stop the machine and you want to reset the switch, so it is not permissible to only re-press this button to restart the machine. And the machine can only be started by re -closing the main switch first.

10. If some machines are equipped with a local shutdown system, especial care should be taken. Read the instruction manuals attached with the machine carefully. In such machines with a local shutdown system, temperature will rise because pressure or vac uum will occur after they have been used for a period.

11. If the operators employed cannot read or write, the owner has the duty to explain to them clearly where dangers exist and warn them that special attention should be paid.

12. The cleaning, lubricating and oiling of the grinding machinery or its parts and components may be carried out only when the machine is stopped. If you must climb on or enter the machine to do such work, the mandatory provisions shall be made without exception: the power supply of motors must be cut off completely and the switch must be locked!

13. Be careful, sampling from inside the machine can never be carried out unless there is not any danger. Usually, the samples can be taken from the pipe under the machine instead of inside machine.

14. Clear off the deposited dust, dirties and materials frequently. Keeping the machine clean can enhance production safety and the cleaning level of workshop, and is also beneficial to dust explosion prevention.

15. If oil (grease) leakage occurs, clean it immediately and seal well the place where leakage occurs, for oil or grease leaked on the floor will easily bring about hazards to the operators.

16. In production operation, the feed machine must be equipped with safety devices, which may be neither removed and abandoned nor reduced in functions. Otherwise, we are not responsible for any accidents resulted here from, and reserve the right to ascertain where the responsibility lies.

17. Please execute the special regulations on accidents prevention in the operating instructions provided by us.

18. Only the trained professionals are allowed to operate the machine and equipment manufactured by our Company.

19. Measures for environmental protection if you decide not to use the machine any longer, the measures for environmental protection and reutilization should be taken: drain the liquids inside the machine (like motor oil, gearbox oil, brake oil and coolant etc.) into special containers and send them to the preparation workshop. The plastic parts shall be picked out for reutilization. The metal parts shall be sorted out so as to be crushed or scraped.

2. Enterprises are obligate to execute following regulations to guarantee operators' safety.

3. The shield caps for belts and chains must be mounted and closed at any moment. It is very dangerous to personal safety, if they are open or disassembled. This point is also applicable for the preventive device of manipulator.

4. The safety limit switches, interlinking cylinders, revolution monitors and solenoid valves or locking electromagnets of the door interlocking devices should always be kept in good order. The safety limit switch may not be overlapped or discarded.

5. The grating cover plate on the grinding machine, grid bar or guard grating are usually installed and delivered together with the machine. They can only be disassembled with tools. And the machines with such kind of devices can never put into work until the above-said devices have been properly installed.

6. The driving motor must be switched off completely when carrying out inspection, commissioning, repair and maintenance. This can be realized through a full-phase separating and lockable switch installed near the machine or on the operation desk and control panel on the site. It is not enough only to screw off the fuse wire!

7. If the grinding machines need other energy like pneumatic, hydraulic, steam and hot water energy, it is necessary to cut off their energy supply or turn off the switch, and eliminate the pressure in the internal pipeline system of the machine.

8. As for handling heated or cooled parts and components of the machine, especial care should still be taken for the danger of burning possibility.

9. If you have pressed the emergency stop switch to stop the machine and you want to reset the switch, so it is not permissible to only re-press this button to restart the machine. And the machine can only be started by re -closing the main switch first.

10. If some machines are equipped with a local shutdown system, especial care should be taken. Read the instruction manuals attached with the machine carefully. In such machines with a local shutdown system, temperature will rise because pressure or vac uum will occur after they have been used for a period.

11. If the operators employed cannot read or write, the owner has the duty to explain to them clearly where dangers exist and warn them that special attention should be paid.

12. The cleaning, lubricating and oiling of the grinding machinery or its parts and components may be carried out only when the machine is stopped. If you must climb on or enter the machine to do such work, the mandatory provisions shall be made without exception: the power supply of motors must be cut off completely and the switch must be locked!

13. Be careful, sampling from inside the machine can never be carried out unless there is not any danger. Usually, the samples can be taken from the pipe under the machine instead of inside machine.

14. Clear off the deposited dust, dirties and materials frequently. Keeping the machine clean can enhance production safety and the cleaning level of workshop, and is also beneficial to dust explosion prevention.

15. If oil (grease) leakage occurs, clean it immediately and seal well the place where leakage occurs, for oil or grease leaked on the floor will easily bring about hazards to the operators.

16. In production operation, the feed machine must be equipped with safety devices, which may be neither removed and abandoned nor reduced in functions. Otherwise, we are not responsible for any accidents resulted here from, and reserve the right to ascertain where the responsibility lies.

17. Please execute the special regulations on accidents prevention in the operating instructions provided by us.

18. Only the trained professionals are allowed to operate the machine and equipment manufactured by our Company.

19. Measures for environmental protection if you decide not to use the machine any longer, the measures for environmental protection and reutilization should be taken: drain the liquids inside the machine (like motor oil, gearbox oil, brake oil and coolant etc.) into special containers and send them to the preparation workshop. The plastic parts shall be picked out for reutilization. The metal parts shall be sorted out so as to be crushed or scraped.

8/20/2013

Muyang SFSP Hammer Crusher

The slow speed type of SFSP grinding machine is specially used for crushing raw materials for egg-layer feeds, and the double s peed type, besides this crushing function, can also be used for grinding feedstuff.

Features:

1. Discharged granules are uniform and full, suitable for crushing egg-layer feeds;

2. Fully optimized hammer arrangement, enabling the crusher to increase the throughput;

3. The rotor that rotates in co rotation and reversion can increase the service life of wearing parts;

4. The operating gate is equipped with a safety interlocking device, ensuring that the motor cannot be started up when the operating gate is open;

5. It can be equipped with a double speed motor (except SFSP56×80), to realize multiple purposes of one machine, which can both crush coarse materials and grind fine materials;

6. The most advanced frequency conversion feeder or magnet belt feeder can be equipped, making it work stable.

Installation and adjustment:

1. Normally, the machine is delivered as a complete set, so when the package is opened, first carefully check if it is damaged in transportation;

2. The main shaft and motor of the machine are directly driven by a pin coupling, and the motor is directly installed on the curs her base with screw holed. The crusher is connected with the foundation by dampers.

3. Due to the high noise of the crusher, it is suggested to put the machine inside a basement or an isolated room. The installation site should be solid and spacious. Note that enough space should be reserved around the grinding machinery for convenient maintenance and component replacement.

Features:

1. Discharged granules are uniform and full, suitable for crushing egg-layer feeds;

2. Fully optimized hammer arrangement, enabling the crusher to increase the throughput;

3. The rotor that rotates in co rotation and reversion can increase the service life of wearing parts;

4. The operating gate is equipped with a safety interlocking device, ensuring that the motor cannot be started up when the operating gate is open;

5. It can be equipped with a double speed motor (except SFSP56×80), to realize multiple purposes of one machine, which can both crush coarse materials and grind fine materials;

6. The most advanced frequency conversion feeder or magnet belt feeder can be equipped, making it work stable.

Installation and adjustment:

1. Normally, the machine is delivered as a complete set, so when the package is opened, first carefully check if it is damaged in transportation;

2. The main shaft and motor of the machine are directly driven by a pin coupling, and the motor is directly installed on the curs her base with screw holed. The crusher is connected with the foundation by dampers.

3. Due to the high noise of the crusher, it is suggested to put the machine inside a basement or an isolated room. The installation site should be solid and spacious. Note that enough space should be reserved around the grinding machinery for convenient maintenance and component replacement.

8/18/2013

Nanhai Petrochemical Steel Structure Project

Muyang steel structure company can provide civil steel structure buildings, tunnel & bridge steel structure, ship and ocean facility steel structure; moreover its steel transport infrastructure is also one of the global market leaders.

Muyang steel structure company now has four stores. There are 13 main shop production bays, with a total area of 47,000 square meters. The target is 170 kg/m, or approximately 8,000 metric tons in full production. In 2012, the company from a variety of mixed-use facility that allows 50% of capacity can produce about 4,000 tons hybrid structural steel per month. At the rate of 10 tons per man, the company now has 400 stuffs. The staffing arrangement is based upon the project sales, so if there is a large project, additional staff will be added to increase output by 1000 tons. In 2013, after the third production base is completed, steel company will be fully up and running.

There are large of successful stories on Muyang steel structure engineering. One is the Nanhai Petrochemical Project which is currently the largest Sino-foreign joint venture project for the petrochemical industry in China. Total Investment in the project was over USD $4.5 billion, making this the single largest foreign investment project in China's petrochemicals industry. The heart of the complex is an 800,000 ton per annum (tpa) ethylene cracker. Other major features of the complex are a 560,000 tpa styrene monomer, a 250,000 tpa propylene oxide plant, a 320,000 tpa mono-ethylene glycol plant, a 240,000tpa polypropylene plant, a linear low density polyethylene/high density polyethylene plant of 300,000 tpa, and a low density polyethylene plant of 150,000 tpa; plus integrated support facilities and utilities.

Muyang steel structure is so well-known in the field of steel construction, and it has a large a share in global, then if you want to get a steel project, you can contact Muyang.

Muyang steel structure company now has four stores. There are 13 main shop production bays, with a total area of 47,000 square meters. The target is 170 kg/m, or approximately 8,000 metric tons in full production. In 2012, the company from a variety of mixed-use facility that allows 50% of capacity can produce about 4,000 tons hybrid structural steel per month. At the rate of 10 tons per man, the company now has 400 stuffs. The staffing arrangement is based upon the project sales, so if there is a large project, additional staff will be added to increase output by 1000 tons. In 2013, after the third production base is completed, steel company will be fully up and running.

There are large of successful stories on Muyang steel structure engineering. One is the Nanhai Petrochemical Project which is currently the largest Sino-foreign joint venture project for the petrochemical industry in China. Total Investment in the project was over USD $4.5 billion, making this the single largest foreign investment project in China's petrochemicals industry. The heart of the complex is an 800,000 ton per annum (tpa) ethylene cracker. Other major features of the complex are a 560,000 tpa styrene monomer, a 250,000 tpa propylene oxide plant, a 320,000 tpa mono-ethylene glycol plant, a 240,000tpa polypropylene plant, a linear low density polyethylene/high density polyethylene plant of 300,000 tpa, and a low density polyethylene plant of 150,000 tpa; plus integrated support facilities and utilities.

Muyang steel structure is so well-known in the field of steel construction, and it has a large a share in global, then if you want to get a steel project, you can contact Muyang.

8/14/2013

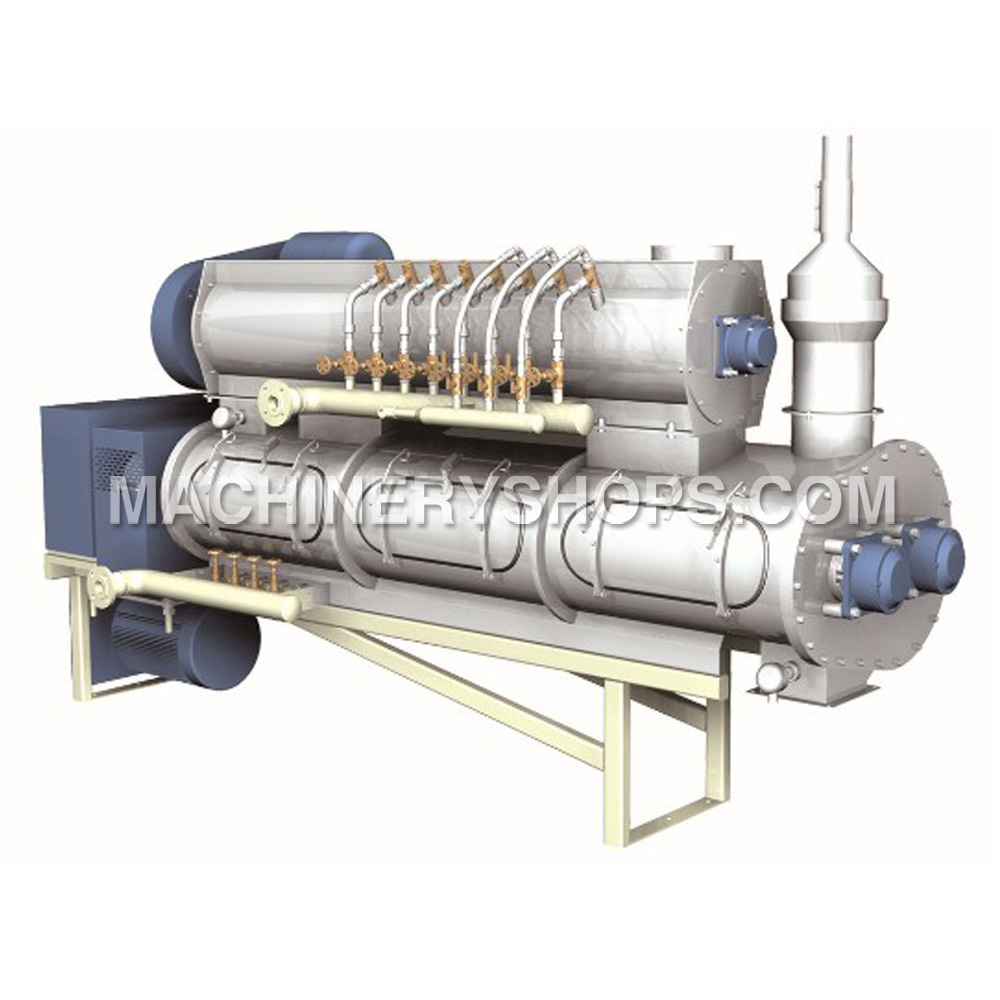

Your Best Choice on Muyang Extruder

Muyang has completed successfully over 3000 various animal and food construction engineering all over the world. Muyang professional installation team, after experiencing numerous hardships and tests, always coordinate allocation of quality installation and construction period and ensure the shortest construction duration on the basis of excellent design of Muyang in order to help you seize market opportunities. The combination of leading process design and high-efficiency ensures your feed mill to take the lead in the world within 3-5 years in future.

Now, most Chinese technology of extruder derives from abroad and the technology is mainly applied for the fields of plastic grease and food processing while it has not been heavily used in pet food processing. Muyang pet food specific twin-screw cooking extruder has following advantage:

Be able to produce pellet of granularity <1.0mm;

Wide application for raw materials, without restriction; Suitable for materials(oil content more than 17%, up to 25% for maximum; meat content up to 35% for maximum);

Finished product features good quality, even appearance, no strict requirements in capacity;

More varieties stable-running and ease of operation.

How to ensure the uniformity of material shape is also a problem in the process. Steady state of screw structure helps to enhance ripening uniformity of materials in the screw. Fully intermeshing twin-screw extruding machine of zero gap contributes to effectively controlling the shearing, so as to ensure consistent the pellet expansion coefficient and ripening time of all materials in the extruding barrel. The patent structure of steady outflow of feeding device and double-mold technology can effectively ensure consistent each point of the material flow rate and extruded pellet uniform in length.

Now, most Chinese technology of extruder derives from abroad and the technology is mainly applied for the fields of plastic grease and food processing while it has not been heavily used in pet food processing. Muyang pet food specific twin-screw cooking extruder has following advantage:

Be able to produce pellet of granularity <1.0mm;

Wide application for raw materials, without restriction; Suitable for materials(oil content more than 17%, up to 25% for maximum; meat content up to 35% for maximum);

Finished product features good quality, even appearance, no strict requirements in capacity;

More varieties stable-running and ease of operation.

How to ensure the uniformity of material shape is also a problem in the process. Steady state of screw structure helps to enhance ripening uniformity of materials in the screw. Fully intermeshing twin-screw extruding machine of zero gap contributes to effectively controlling the shearing, so as to ensure consistent the pellet expansion coefficient and ripening time of all materials in the extruding barrel. The patent structure of steady outflow of feeding device and double-mold technology can effectively ensure consistent each point of the material flow rate and extruded pellet uniform in length.

8/11/2013

Successful Story on Muyang Group

Jiangsu Muyang Group Ltd. was established in 1967, and was the earliest professional manufacture appointed by government. Now, Muyang is not only the National Standardization Committee Secretariat unit on feed machinery, but also the only company with the title of "China Famous Brand". The main products on Muyang are feed engineering, aquaculture engineering, oil engineering, steel structure engineering, agricultural machines; and the company has a strong ability providing solutions for whole industrial chain systems.

After years of rapid development, Muyang has been the leader in a number of industries and enterprises at home and abroad. In China, Muyang’s market share is more than 60 percent in feed industries, ranking the top; the storage silo from Muyang carries on largest-ton accounts, capturing about 40 percent market share; while Muyang has whole biomass energy industry, establishing service network in more than 60 countries worldwide, with the top grass, straw processing technology; addition, Muyang Group has various types of sophisticated extrusion technologies, with many domestic and foreign experts teams, leading the group to be number one.

Muyang develops more than 30 new products, and promote over 60 old products, and its patent applications are nearly 700 in total. Muyang has a rich experience in research and development of feed machinery, with strong research capabilities. Also, Muyang in some extend represents the top level in the field of feed machinery with its grinding technology, hybrid technology, extruder technology, and granulating technology, and the technology has reached or caught up with international advanced level.

After years of rapid development, Muyang has been the leader in a number of industries and enterprises at home and abroad. In China, Muyang’s market share is more than 60 percent in feed industries, ranking the top; the storage silo from Muyang carries on largest-ton accounts, capturing about 40 percent market share; while Muyang has whole biomass energy industry, establishing service network in more than 60 countries worldwide, with the top grass, straw processing technology; addition, Muyang Group has various types of sophisticated extrusion technologies, with many domestic and foreign experts teams, leading the group to be number one.

Muyang develops more than 30 new products, and promote over 60 old products, and its patent applications are nearly 700 in total. Muyang has a rich experience in research and development of feed machinery, with strong research capabilities. Also, Muyang in some extend represents the top level in the field of feed machinery with its grinding technology, hybrid technology, extruder technology, and granulating technology, and the technology has reached or caught up with international advanced level.

8/07/2013

Tips on Repairing Grinding Machine

Grinding machine is one of the main equipments on feed industries. The operating reliability affects directly the following process. Therefore, analyzing and dealing with the usual faults on the machines in a short time is very important. Grinder system mainly includes mill and motors. Corresponding fault can be divided into mechanical failure and electrical failure.

Vibrating mill generally adopts motor directly coupled device, which connection is simple and easy to maintain. However, if you can’t make the two connect well, you will cause the overall vibration.

1.The motor rotor and the crusher rotor of the grinding machine are in different axis. Now, you can move the position of the motor or add the pad under the motor to adjust the two into concentricity.

2.The reason why the two rotors are in different axis is that two support bearing surfaces are not in the same surfaces. In this situation, you can place copper at the bottom of bolster, or add adjustable wedge at the bottom of bolster to make sure the same axis.

3.Grinding chamber is vibrating largely. The reason is that the coupling and coupling misalignment rotor are out of the one axis, or the flat hammer is asymmetrical. In this situation, you can take the appropriate method withered entire coupling and motor connection depending on the type couplings: When the hammer is with different quality, it should be re-matched to each hammer, to make hammers be symmetrical, so that the relative hammer chip error is less than 5G.

4.Original balance is destroyed. You should do motor balancing test after repair to be done to ensure that the overall balance.

5.When grinder system's bolts loose, you should tighten anchor bolts to foundation while installing or maintaining. Also, you should install damping device to reduce vibration.

6.Hammer broken or crushed indoor hard debris, which will cause rotor imbalance and vibrations. Therefore, to regularly check for badly worn hammer of the grinding machinery is so necessary. In replacement, the parts should be symmetrical replaced; when occur a normal voice in the grinding process, the operator should stop the machine right now to check the matter.

Vibrating mill generally adopts motor directly coupled device, which connection is simple and easy to maintain. However, if you can’t make the two connect well, you will cause the overall vibration.

1.The motor rotor and the crusher rotor of the grinding machine are in different axis. Now, you can move the position of the motor or add the pad under the motor to adjust the two into concentricity.

2.The reason why the two rotors are in different axis is that two support bearing surfaces are not in the same surfaces. In this situation, you can place copper at the bottom of bolster, or add adjustable wedge at the bottom of bolster to make sure the same axis.

3.Grinding chamber is vibrating largely. The reason is that the coupling and coupling misalignment rotor are out of the one axis, or the flat hammer is asymmetrical. In this situation, you can take the appropriate method withered entire coupling and motor connection depending on the type couplings: When the hammer is with different quality, it should be re-matched to each hammer, to make hammers be symmetrical, so that the relative hammer chip error is less than 5G.

4.Original balance is destroyed. You should do motor balancing test after repair to be done to ensure that the overall balance.

5.When grinder system's bolts loose, you should tighten anchor bolts to foundation while installing or maintaining. Also, you should install damping device to reduce vibration.

6.Hammer broken or crushed indoor hard debris, which will cause rotor imbalance and vibrations. Therefore, to regularly check for badly worn hammer of the grinding machinery is so necessary. In replacement, the parts should be symmetrical replaced; when occur a normal voice in the grinding process, the operator should stop the machine right now to check the matter.

8/05/2013

Muyang High Quality Water-drop 968 Hammer Mill

Grinding machine is the machine which can make large solid materials into small required sizes. Mainly, the grinding machines consist of coarse crushing, fine, wind conveying devices which can make grinding effects via the form of high-speed kocks. It uses wind energy to make powders, eliminating the conventional screening procedures. The main application is in thmining, building materials and other industries.

According to the crushed size, the feed mill can be divided into primary crusher, broken machine, fine grinding machine, ultrafine mill. In the grinding process, there are four forces on the solid roll including breaking, shearing, impact and polishing. Breaking is mainly used in coarse, medium broken, hard material and bulk material; shearing is mainly used in crushing, suitable for ductile materials; impact is mainly used in crushing, grinding, fine grinding, suitable for the brittle material; polishing is mainly used in fine grinding, suitable for small and fine particles.

Hammer mill is the most widely used machine is the feed industry which has the advantages of improved production efficiency to reduce power consumption. Advanced waterdrop-shaped crushing chamber design, "W” shaped double grinding structure, output increases by 25%Sliding fully-opening access door,interlocked screen hold-down fixture, more convenient operation and maintenance. Fully optimized hammer arrangement can adjust hammer screen space. It also has good effect on high-precision dynamic balancing, which ensures more stable operation, lower noise, better performance. The high-precise 14px-diameter rotor is tested by dynamic balancing, enhancing grinding efficiency.

According to the crushed size, the feed mill can be divided into primary crusher, broken machine, fine grinding machine, ultrafine mill. In the grinding process, there are four forces on the solid roll including breaking, shearing, impact and polishing. Breaking is mainly used in coarse, medium broken, hard material and bulk material; shearing is mainly used in crushing, suitable for ductile materials; impact is mainly used in crushing, grinding, fine grinding, suitable for the brittle material; polishing is mainly used in fine grinding, suitable for small and fine particles.

Hammer mill is the most widely used machine is the feed industry which has the advantages of improved production efficiency to reduce power consumption. Advanced waterdrop-shaped crushing chamber design, "W” shaped double grinding structure, output increases by 25%Sliding fully-opening access door,interlocked screen hold-down fixture, more convenient operation and maintenance. Fully optimized hammer arrangement can adjust hammer screen space. It also has good effect on high-precision dynamic balancing, which ensures more stable operation, lower noise, better performance. The high-precise 14px-diameter rotor is tested by dynamic balancing, enhancing grinding efficiency.

8/01/2013

Features on Extruder

Extruder has a relatively superiority in production than other normal technologies. This is because in most cases, this extrusion integrates many different functions which can perform simultaneously mixing, crushing, shearing, cooking, and form a drying process.

Extrusion has the following functions and features:

(1)The versatility of the extruder

The versatility of the extruder is mainly manifested in different materials what are suitable for processing, while processing the same kind of materials required to achieve different degreeofcuring. The reason why an extruder can achieve multi-function is mainly in the following three aspects:

a.Screw configuration can use combined type, just change a little, that can provide different material shear force;

b.A feeding device has many forms, but the material discharge area can be adjusted;

c.In the process, parameters can be adjusted according to the details.

(2)Product's uniqueness

The extrusion operation capable of producing products and product shape is often very difficult, and other technial means can't get.

(3)High quality products

The pressing operation can be used as a very effective high temperature short time processing methods, effectively reducing anti-nutritional factors and eliminating bacteria.

(4)Effective use of energy

The product obtained after extrusion operations ripening degree has been greatly improved, compared to other process, or means to get so high in the degree of maturation of the request, the extrusion can take full advantage of the steam to reduce energy consumption , thereby reducing processing costs.

(5)The minimum amount of industrial waste

The extruder effectively prevents the plant wastewater, which for those feed producers is a very prominent advantage on how to reduce the environmental impact on the surrounding pressure.

Extrusion has the following functions and features:

(1)The versatility of the extruder

The versatility of the extruder is mainly manifested in different materials what are suitable for processing, while processing the same kind of materials required to achieve different degreeofcuring. The reason why an extruder can achieve multi-function is mainly in the following three aspects:

a.Screw configuration can use combined type, just change a little, that can provide different material shear force;

b.A feeding device has many forms, but the material discharge area can be adjusted;

c.In the process, parameters can be adjusted according to the details.

(2)Product's uniqueness

The extrusion operation capable of producing products and product shape is often very difficult, and other technial means can't get.

(3)High quality products

The pressing operation can be used as a very effective high temperature short time processing methods, effectively reducing anti-nutritional factors and eliminating bacteria.

(4)Effective use of energy

The product obtained after extrusion operations ripening degree has been greatly improved, compared to other process, or means to get so high in the degree of maturation of the request, the extrusion can take full advantage of the steam to reduce energy consumption , thereby reducing processing costs.

(5)The minimum amount of industrial waste

The extruder effectively prevents the plant wastewater, which for those feed producers is a very prominent advantage on how to reduce the environmental impact on the surrounding pressure.

Subscribe to:

Posts (Atom)