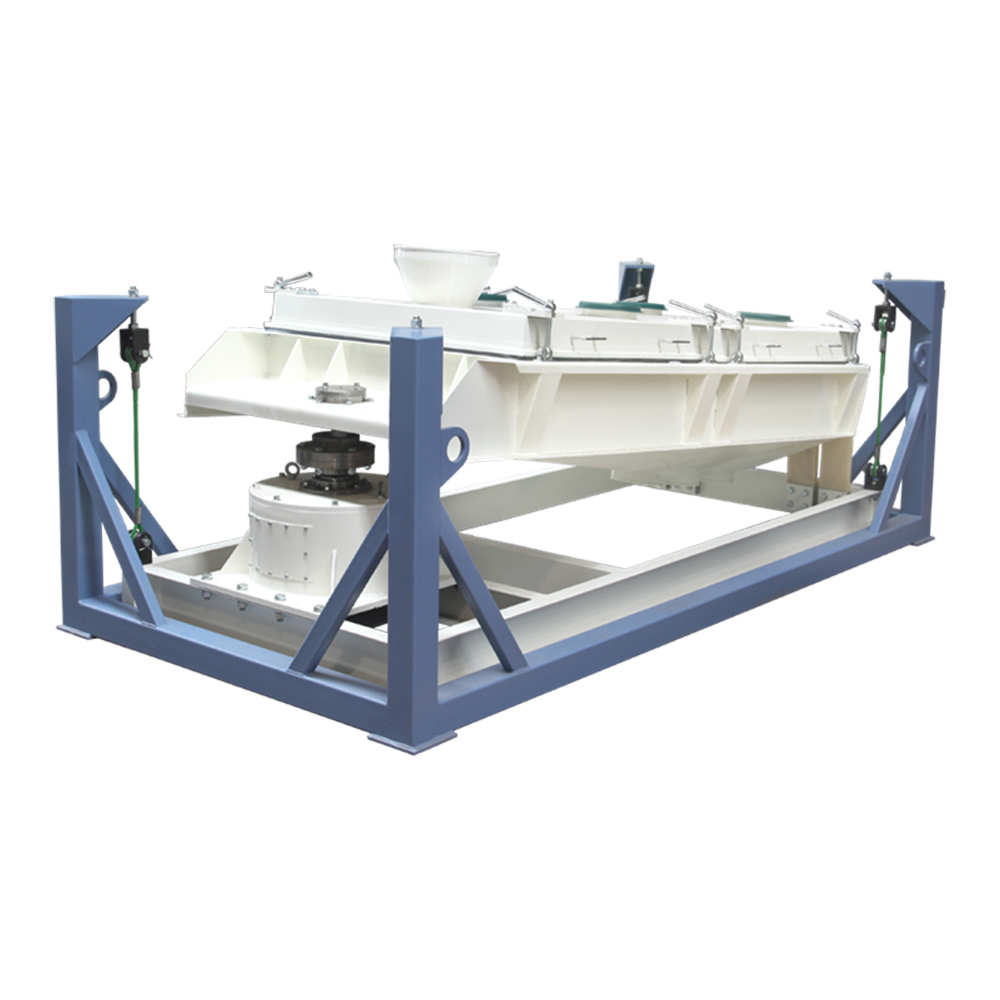

Muyang SFJH series Rota-shake sifter consists of a machines stander, a driving device, a sieve body, a sieve carrier, a tail support mechanism and hanging mechanism.

The power is transmitted through the V-type belt from the motor to the driving device and the sieve body is driven by the driving device with a certain inclination. Since the driving device is equipped with an eccentric device, the motional track of the sieve body from the feeding end to the discharge end changes gradually from the horizontal circular motion to elliptic motion and finally to similar reciprocating straight-line motion. The feedstuffs enter the sieve body from the feed inlet.

Under the action of the circular motion of the feeding end of the sieve body on the feed machinery, the feedstuffs are distributed uniformly on the width of the sieve cover rapidly and graded automatically. Thus lower part of the feedstuffs with smaller particle size passes through the sieve rapidly, while the upper part of feedstuffs with bigger particle size moves towards the lower end (discharge end) along the inclined surface of the sieve body. Since there is not stirring or vertical jumping during the movement, smaller particles always hug closely to the sieve cover and can pass through the sieve at all time.

At the discharge end, the sieve body makes similar reciprocating straight-line motion and weakens the screening effect, thus enabling particles bigger than the sieve aperture to move towards the outlet rapidly till the particles are discharged out. Thus the material screening and grading are completed.