Welcome to

Muyang Group!

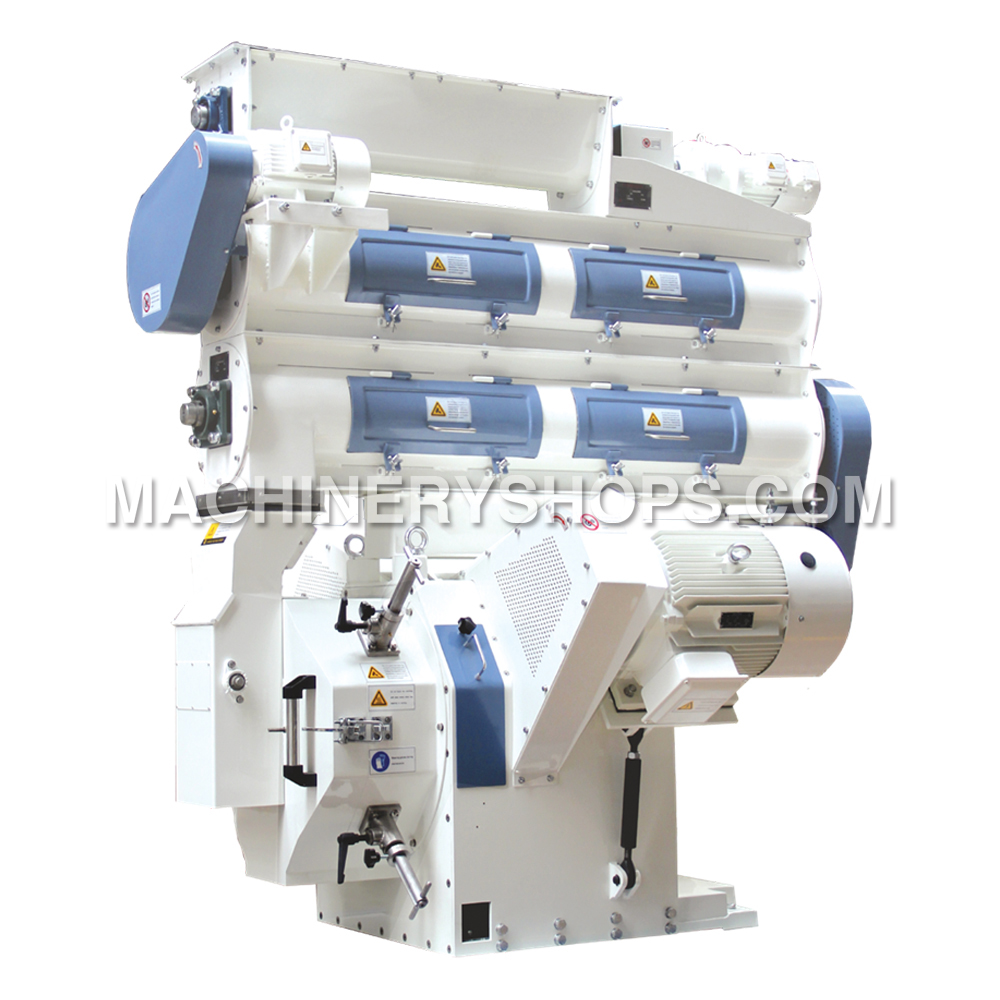

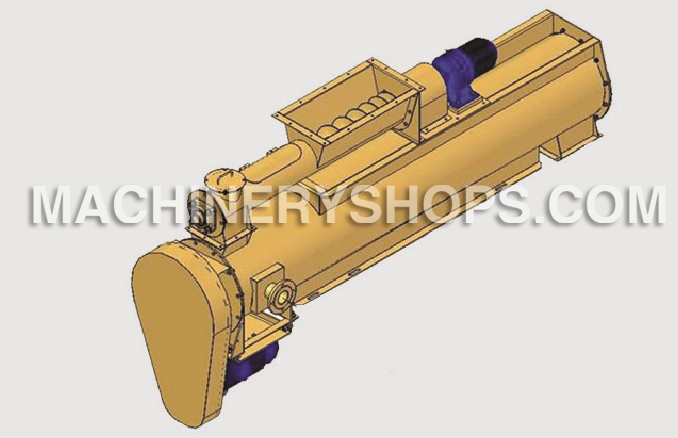

If you want to shred or crush aggregate material into smaller pieces on your farm, you need to use hammer mill whose basic principle is straightforward. A hammermill is essentially a steel drum containing a vertical or horizontal rotating shaft or drum on which hammers are mounted. The hammers are free to swing on the ends of the cross, or fixed to the central rotor. The rotor is spun at a high speed inside the drum while material is fed into a feed hopper. The material is impacted by the hammer bars and is thereby shredded and expelled through screens in the drum of a selected size. The hammermill can be used as a primary, secondary, or tertiary crusher.

Muyang Grinding Hammer Mill is most customers' choices as they can help them save 30 million yuanes per year. Now, I will tell you why you should choose Muyang

Feed Machine, there are three reasons here:

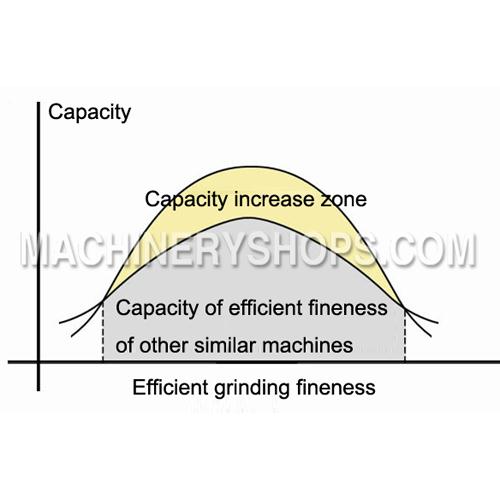

1. High capacity

China authority proves and lots of customers witness on the scene, Muyang Third Gerneration SWFP Series Fine-Grinding Hammermill has made revolutionary breakthroughs in performance.

①Guangxi HuaGang: crushing corn, moisture 13.8%

Φ1.0mm, measured capacity up to 15.23 t/h, ton power consumption low to 11.2 kW*h/t

Φ1.5mm, measured capacity up to 16.80 t/h(Maximum up to 18.93 t/h), ton power consumption low to10.2 kW*h/t

②Wuhu Tequ: crushing corn, moisture 11.2%

Φ2.0mm,measured capacity up to 30.7t/h, ton power consumption low to 5.28kW.h/t

2. Low power

One machine (160kW) can yearly save 498,000 kWh and reduce cost of 298,800 yuanes. Hence, choosing SWFP series, saving 30 million per year in ultra-fine grinding is no longer a dream.

3. Superstable running

Helped by Special grinding chamber optimization design, the current keeps stable in the process of grinding running with fluctuations not more than 2%. Taking feed company of annual output 100,000 tons as an example, it needs about 60,000 tons of corn to crush, compared with double rotor crusher, Muyang Third Generation SWFP Series Fine-Grinding Hammermill (SWFP66 × 100C, 160kW) can save about 8.3 kW.h / t, equal to 498,000 kWh of electricity per year, a reduce of annual cost 298,800 yuanes according to 0.6 yuan/ kilowatt-hour.

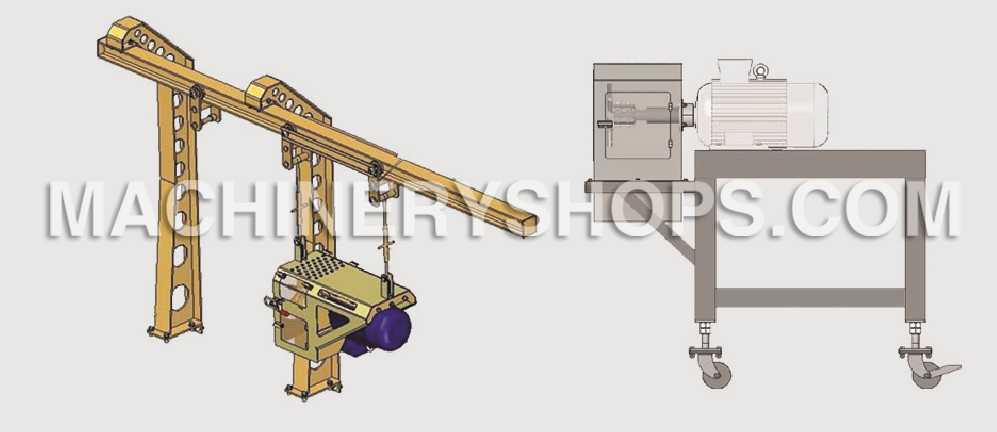

Series Fine-Grinding Hammermill can realize significantly higher capacity and lower ton power consumption, and it is suitable for coarse-grinding and micro-grinding of various granular grain materials, such as corn, sorghum, rice, wheat, soybean meal, cottonseed meal, rapeseed meal. It is also appliable for micro-grinding of various large, medium and small-sized aquatic feed and special feed production. It is also suitable for micro-grinding in the industry of pharmaceutical, alcohol and solvent.

So, if you want to know more on

Muyang Products, you can visit here : http://www.machineryshops.com/, and I believe you can find your ideal one.