If you have an improved, cheaper and safer end product you will have the edge over competitor and eventually your profit ratio. For feed manufacturing industry, technology that help feed manufactures keep leading in the industry has become the primary consideration for making the investment decision, be it greenfield or upgraded project.

For livestock feed production, pretreatment technology is very important, and the basic type of processing used within feed mills usually is pellet conditioner. As concerns over feed cost increased, new pretreatment technologies are asked to widen the scope of available raw materials. And higher standards on feed nutrition and feed safety in breeding farms also require improved technologies and equipment for production, especially for young animal feed. For these reasons, expander used in pretreatment has become more and more popular in processing lines. However, gelatinization level of end product of traditional expander is limited to 60%. When requirement to starch gelatinization comes up to 70~75%, extruder is a better choice than expander, but it also faces problems of reduced output and increased energy consumption.

As a technology problem solver, Muyang introduces a new technology specialized for piglet feed production. The so call "fully extrusion and low-temperature pelleting system" may initially be more expansive than the expander and pelleting system, but when makes a simple comparison of the increased profit from high quality end product and the reduced tonnage power consumption, it can normally be shown to be cost effective, and this is without taking into account the probable increased efficiency of the extruder machinery itself.

Feed intake efficiency comparison

Results of tests demonstrated that piglets fed with feed produced by fully extrusion and low-temperature pelleting line showed significant improvement on feed intake, weight gain and intestinal health. It is because:

1) Fully extrusion process can achieve products tasty flavor and better palatability;

2) Fully extrusion and low temperature pelleting can diminish nutritional ingredients loss during processing, and ensure enough nutrition and energy for weanling pigs, resulting in increased weight gain;

3) Fully extrusion can contribute to higher starch gelatinization and eliminates the effects of anti-nutritional factors and toxins, which is good for intestinal health.

12/16/2014

12/09/2014

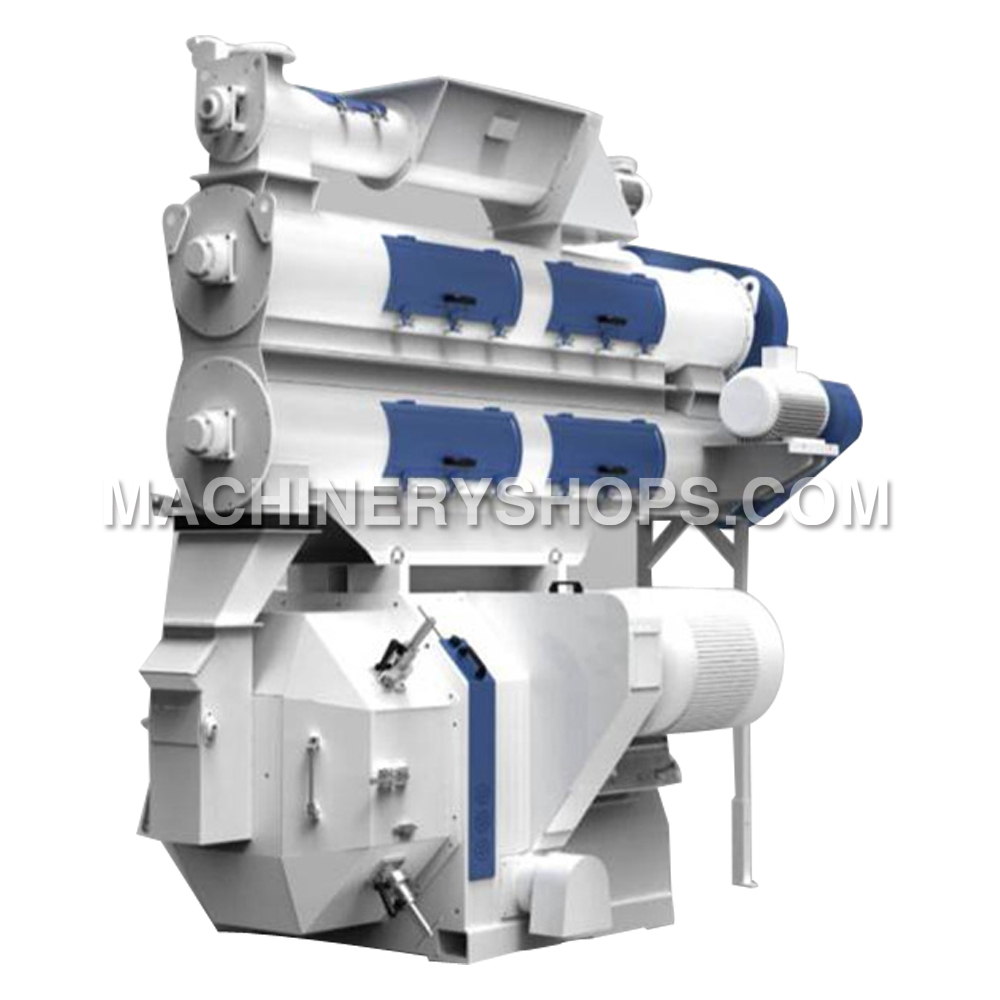

Animal Pellet Feed Production Line

Animal pellet feed production line is the core equipment for feed manufacturers, which can complete the magnetic separation, crushing, mixing, granulating, lifting, cooling, screening, product packaging and dust removal by ventilation, electrical control and other functions, this paper will introduce what equipment does animal pellet feed production line have?

According to the process flow, complete feed production line can be divided into four sections, and each section has specific equipment:

1.Preclean and grinding section: in this system, feed raw materials will be received, and hammer mill machine will be used to grinder materials.

2.Mixed section: feed materials which is stored in the mixing chamber will be mixed by twin shaft paddle mixer or screw mixer.

3.Pellet-making, cooling section: in this section, ring die pellet mill or flat die pellet machine is the main animal pellets feed making machine and hot pellets feed made by feed making machine will be cooled by counter flow cooler.

4.Sieving and packing section: Pellet feed after sieving can be packed, in the section, you can choose automatic bagging scale or manual packing.

According to the process flow, complete feed production line can be divided into four sections, and each section has specific equipment:

1.Preclean and grinding section: in this system, feed raw materials will be received, and hammer mill machine will be used to grinder materials.

2.Mixed section: feed materials which is stored in the mixing chamber will be mixed by twin shaft paddle mixer or screw mixer.

3.Pellet-making, cooling section: in this section, ring die pellet mill or flat die pellet machine is the main animal pellets feed making machine and hot pellets feed made by feed making machine will be cooled by counter flow cooler.

4.Sieving and packing section: Pellet feed after sieving can be packed, in the section, you can choose automatic bagging scale or manual packing.

Subscribe to:

Posts (Atom)