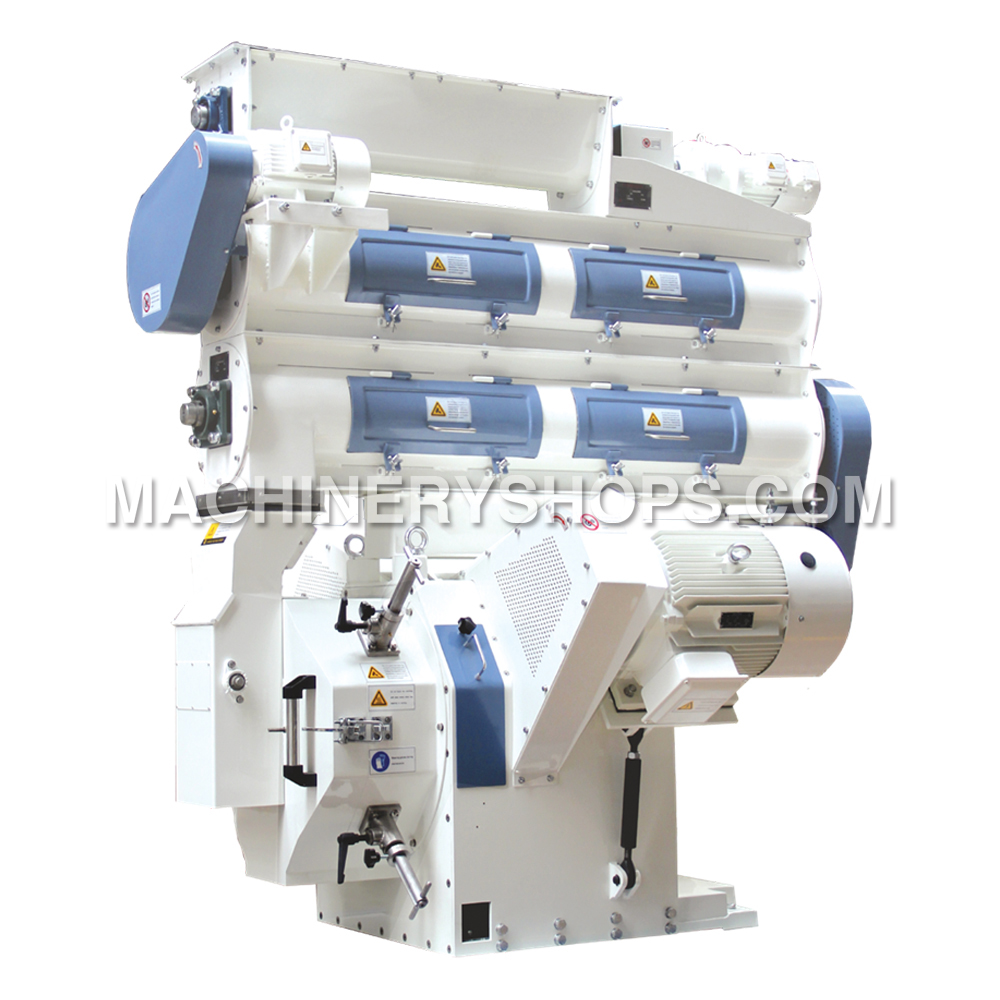

This type of pelleting machine includes two main motors, which are symmetrically installed at both sides of the pellet mill.

The two motors shall rotate in the same direction and finally the ring die shall rotate in clockwise.

The two motors shall startup in star form at the same time, while under normal operation speed the one is transmitted to a triangle connection firstly, and the other also to a triangle operation about five seconds later.

Two motors must run at a same direction and commissioned separately before commissioning and starting of this machine.

Rotor assembly

Main components of rotor assembly are shown in Fig 2.3.

The oil-way of rotor assembly shall be kept unobstructed, after filling the oil from oil nozzle of distributer at rear end, the lubricating oil leading to press roller bearings shall overflow from the seal plate at the end of the press roller after being filled up, and lubricating oil leading to rotor bearings shall overflow from the clearance between the rotor and main shaft disc after being filled up.(It is guaranteed by the oil seal installation direction of the rotor)

Generally, in good lubrication, the service life of the bearings and oil seals of the rotor are longer and they are uneasy to be damaged. It is suggested to ask pellet mill experts of Muyang Group for guide when replacing bearings and oil seals.

Pay attention to abrasion of the cone face of driving flange of the ring die, see Section 7.5 for assembling and disassembling as well as maintenance.

Shear pin assembly

The main parts of the shear pin assembly are shown as Fig.2.5.

When there is large iron block or other impurities entering between the ring die and press roller, in which case, the toque delivered by main shaft will exceed the shear force of the shear pin (part 3), and the shear pin will be sheared off and drove the main shaft rotating with the rotor, the limit switch (part 5) will be cut off to stop the main motor, and take the effect of protecting ring die and press roller.

Restore the Shear pin disc (part 2) to replace a new shear pin after it is sheared off.