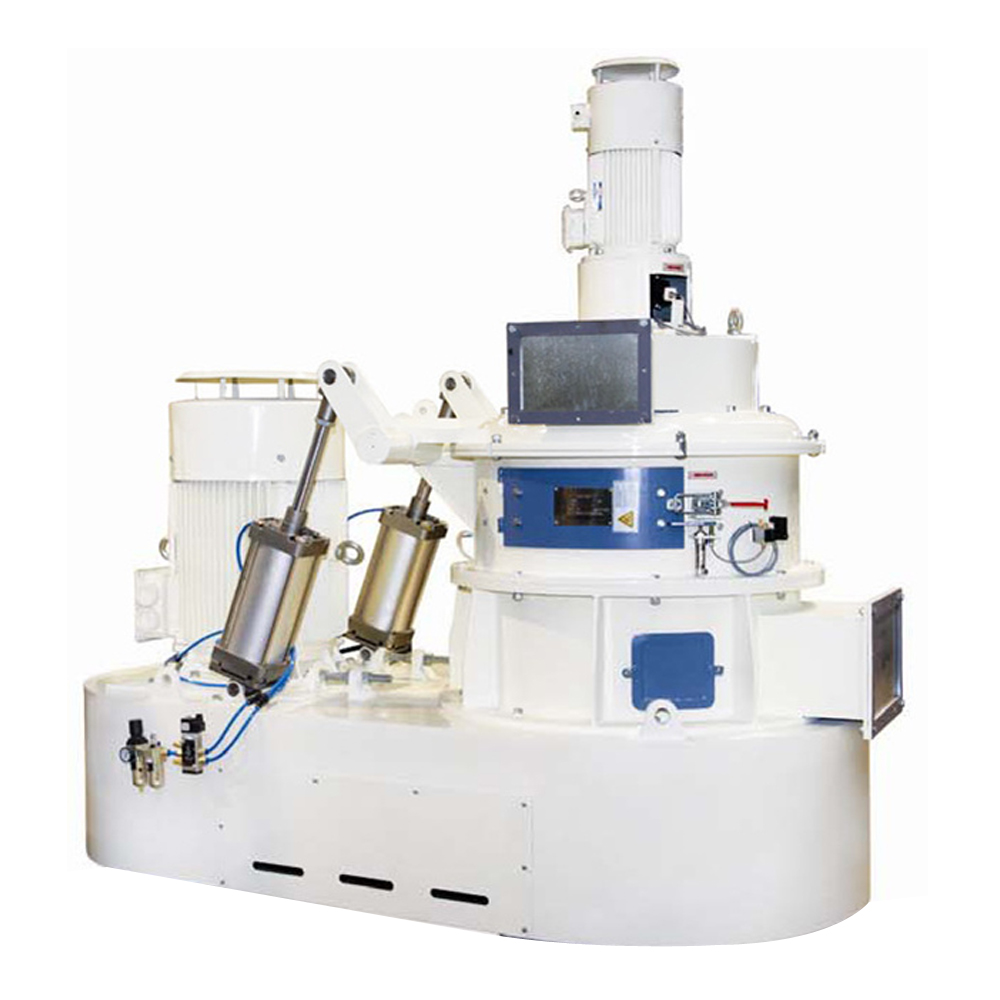

Principal machine

L/D=13.1 to increase material retention time in the extruder;

Combining the shearing effects of both screw and shear lock to increase extrusion efficiency and pellet uniformity;

New material applied in the manufacturing of wear parts prolongs the service life by 2-3 times and ensure stable production.

Requirements to working condition

1. Environment temperature for normal use is within -10~+40℃;

2. Relative moisture content for normal use is within 30~85%;

3. Altitude for normal use is lower than 1000 m;

4. Keep the room where extruder machinery working clean and ventilated;

5. Keep the extruder far away from corrosive gas, explosive gas and steam;

6. Power supply: refer to motor nameplate;air pressure ≧0.6Mpa;

7. Keep enough space around the extruder for easy operation, repair and maintenance;

8. Make sure the machine is level.

9. The vibration should not exceed12 mm•s-1

Production reference

Currently, there are over 100 sets of Muyang MY series single-screw extruder stably running in China and around the world. Satisfied customers include CP Group, DaChan Food, Gold Coin, New Hope Group, Tongwei Group, etc.